Photovoltaic (PV) panels are comprised of individual cells known as solar cells. Each solar cell generates a small amount of electricity. When you connect many solar cells together, a solar panel is created that creates a substantial amount of electricity. PV systems vary in size, depending upon the application: it can vary from small, rooftop-mounted or building-integrated systems with capacities of tens of kilowatts to large utility-based stations that generate hundreds of megawatts of electrical power. There are PV systems that are connected to the power grid (grid-direct or grid-hybrid systems), and there are systems that allow a user to disconnect from the grid (off-grid (or stand-alone) systems).

Photovoltaic (PV) panels are comprised of individual cells known as solar cells. Each solar cell generates a small amount of electricity. When you connect many solar cells together, a solar panel is created that creates a substantial amount of electricity. PV systems vary in size, depending upon the application: it can vary from small, rooftop-mounted or building-integrated systems with capacities of tens of kilowatts to large utility-based stations that generate hundreds of megawatts of electrical power. There are PV systems that are connected to the power grid (grid-direct or grid-hybrid systems), and there are systems that allow a user to disconnect from the grid (off-grid (or stand-alone) systems).

The process of converting light (photons) to electrons generates DC electricity in solar cells. Direct current (DC) electricity can be used to charge batteries and run a variety of electronics, but to supply power to a household or business, DC usually needs to be converted to AC (alternating current) power. The electrical grid transmit power over long distances using AC power. In our households, certain electronics may run on AC power and others use DC power. Once AC power reaches the end user, it can be converted back into DC if needed.

Most of today’s PV systems are modular, which means that they allow the user to add or remove power capacity to the system at any time. These systems give customers the flexibility to adjust their power capacity as the demand changes. In photovoltaic systems, there are many other components besides the solar cells. These components include the wiring, surge protectors, switches, mechanical mounting components, inverters, batteries, and battery chargers. These components are what distributes and stores electricity safely and efficiently and can account of up to half the cost of the total cost of a photovoltaic system. Components that are present in a typical photovoltaic system are:

• Solar panels

• Electrical connections between solar panels

• Output power lines

• Power inverter (converts DC electricity to AC electricity)

• Mechanical mounting equipment

• Charge controller

• Wiring

• Batteries for energy storage

• Electrical meter (for grid-connected systems)

• Overcurrent and surge protection devices

• Power processing equipment

• Grounding equipment

Utilities may use more advanced systems for generating substantial quantities of electricity such as:

• Single axis or double axis tilting systems

• Automatic cooling and cleaning systems

• Fuel cell, battery or other type of power storage systems

• Transmission lines

This equipment enables engineers and technicians to build PV systems that can be integrated into buildings or constructed at an off-site location. If the photovoltaic system is located off-site, transmission lines would need to transport the power from the solar array to the site that requires the power.

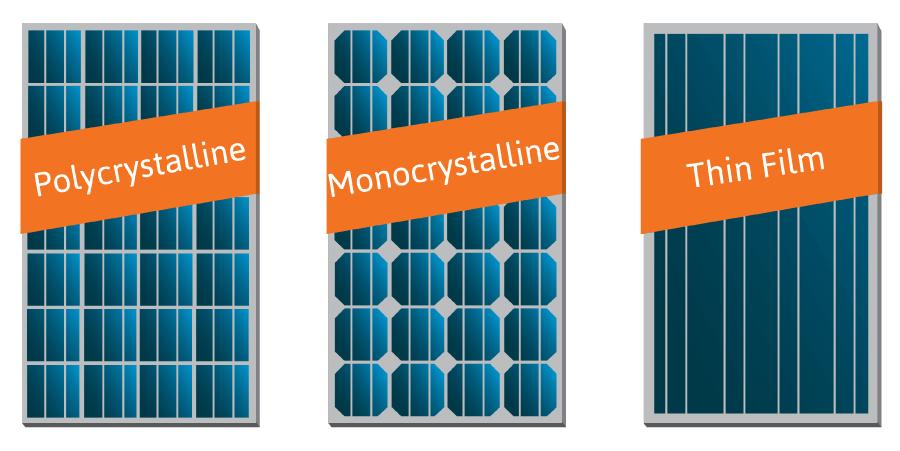

There are three types of solar panels that are widely available for use in photovoltaic systems, (1) monocrystalline, (2) polycrystalline, and (3) amorphous thin-film. Each type of panel has its advantages and disadvantages. The primary differences between these panel types are their cost and efficiency.

Monocrystalline panels have a uniform crystal structure across the entire panel, and can be made from a variety of materials such as amorphous silicon, gallium arsenide, germanium, cadmium telluride, copper indium gallium selenide, and organic polymers. Monocrystalline solar panels have the highest efficiency ratings to date and perform better than other types of panels in low-light conditions. The efficiency also decreases more slowly over time. Monocrystalline solar panels are produced from silicon ingots and are expensive to manufacture. These monocrystalline panels have the highest initial cost; however, the energy savings over time may make the cost worthwhile.

Polycrystalline silicon solar panels have a unique speckled blue color that varies in shade with different areas of the panel. The silicon used in these panels is not homogenous; which means that the crystal structure can be different in various areas of the panel. As a result, polycrystalline solar panels are less efficient than monocrystalline solar panels. Polycrystalline solar panels are less efficient at their operating temperature due to their larger temperature coefficient than monocrystalline solar panels. Due to the reduced power conversion efficiency, a greater number of panels are required to generate the specified power.

Polycrystalline silicon solar panels are less expensive to purchase than monocrystalline silicon solar panels due to the non-homogeneity of the cells. Many customers choose polycrystalline panels over monocrystalline panels due to the reduced cost.

Thin-film solar panels are less efficient than monocrystalline or polycrystalline solar panels and have a shorter lifetime. However, their costs are much lower due to the simple manufacturing methods in comparison with crystalline solar panels. Thin-film solar panels can also be made flexible, whereas crystalline solar panels are much more brittle and will crack if they are bent.

Because thin film panels are less efficient, they are not recommended for use in residential photovoltaic systems. A user would need more thin-film panels than crystalline solar panels (and therefore, more space) to generate a specified amount of electricity. For this reason, thin-film solar panels are used more often by utility companies than by residential customers.

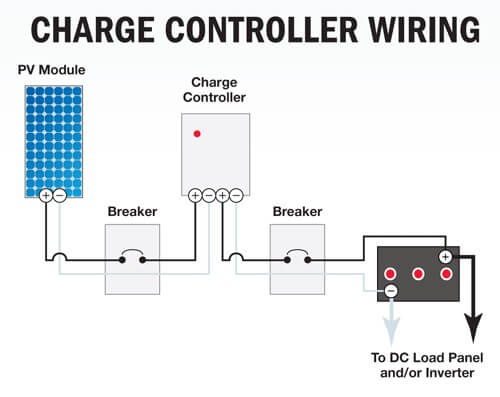

Charge controllers take some of the electricity from the DC current generated by a solar array and use it to charge a battery or a group of batteries. The charge controller regulates the voltage and current generated by a solar array so that it can properly charge the battery or bank of batteries. The power generated by solar panels varies with light (photon) exposure. If a charge controller was not present in the photovoltaic system, the batteries could be overcharged and may be damaged.

The nominal and maximum voltage and current specifications on the charge controller will determine the number of charge controllers required to gather energy from the solar array. If a solar array generates a maximum current of 16 A, but a charge controller only accepts a maximum current of 10 A, the solar array can be divided into two parts. Each half of the array can generate a maximum 8 A of current, and each half of the array can be connected to the 10 A charge controller. The other option would be to use a charge controller with a larger current rating. Most charge controllers have very high current ratings (at least 40 amps), and the need for more than one charge controller only becomes an issue with very large solar arrays.

Batteries are used to store the energy generated by a solar array. Home-based solar arrays generate their largest power output in the middle of the day when most people are away from their homes. If the energy is not used immediately, it can be stored in a battery array. In a grid-hybrid system, any extra electricity generated after the batteries are charged can be sent back to the power grid.

Batteries supply DC power for a certain amount of time. The lifetime of a battery will depend on the current that the battery supplies and the maximum charge the battery can hold. The maximum charge of a battery is typically listed on the battery in units of milliamp-hours (mAh). This unit expresses the current the battery can supply and the amount of time it can supply the current.

There are two types of power inverters that are used in all photovoltaic systems. Grid-direct systems use a grid-tied inverter that can interact with the utility grid. This type of inverter is different from the inverters in off-grid or grid-hybrid systems because it does not run off of batteries. The off-grid and grid-hybrid systems use battery-powered inverters. Both types of inverters perform the same essential function in these systems: they convert DC power to AC power.

In the grid-hybrid and off-grid systems, solar energy that is not used immediately is stored in a battery system. The DC power that is stored in a battery can be converted to AC power using a power inverter. A power inverter is a device that converts DC power into AC power. The battery array in a photovoltaic system can be used to run a power inverter, power electronics or other BOS components. The components can be directly powered using DC power or indirectly using AC power. The DC-to-AC converter is required because almost all home electronics require 110 VAC power.

Safety and grounding equipment is required for safety and fire prevention purposes. Automatic and manual safety disconnects protect the wiring and components of a photovoltaic system from power surges and other equipment malfunctions. They also ensure that your system can be shut down safely for maintenance and repair. In the case of grid-connected systems, safety disconnects also allow a photovoltaic system to be disconnected from the grid; this is important for the safety of people working on the grid transmission and distribution systems.

Grounding equipment provides a low-resistance path from your system to the ground to protect a photovoltaic system against current surges from lightning strikes or other equipment malfunctions. Users will need to create a grounded connection that is common to all of the balance-of-system equipment. This includes any exposed metal (such as the chassis of equipment boxes) that could potentially be touched by the customer or a technician.

The photovoltaic system design depends on the amount of power required for the particular application. The nominal and peak power required, along with how the storage and how the system is connected to the grid will determine the number of panels that are required by the system.

Posted by

Posted by