Fuel cell vehicles (FCV) use fuel cells to power the vehicle’s electric motor. Many FCVs use a fuel cell combined with a battery and supercapacitor to efficiently start-up, power, and utilize the best energy source for constant and peak power. In FCVs, the fuel cell uses oxygen from the air and compressed hydrogen. These vehicles only emit water and heat as byproducts. The major reason for developing automotive fuel cell technology are their efficiency, low or zero emissions, and fuel production from local sources rather than imported sources.

Fuel cell vehicles (FCV) use fuel cells to power the vehicle’s electric motor. Many FCVs use a fuel cell combined with a battery and supercapacitor to efficiently start-up, power, and utilize the best energy source for constant and peak power. In FCVs, the fuel cell uses oxygen from the air and compressed hydrogen. These vehicles only emit water and heat as byproducts. The major reason for developing automotive fuel cell technology are their efficiency, low or zero emissions, and fuel production from local sources rather than imported sources.

Automotive fuel cells can have one or all of the following characteristics:

• A fuel cell is sized to provide all of the power to a vehicle. A battery may be present for startup.

• A fuel cell typically supplies a constant amount of power, so for vehicle acceleration and other power spikes, additional devices are typically switched on such as batteries, ultra or supercapacitors, and so on.

• A fuel cell can be used as the secondary power source. A system can be set up where batteries power the vehicle, and the fuel cell recharges the batteries when needed.

• A fuel cell can run part or all of the vehicle’s electrical system. Sometimes another engine is used for propulsion.

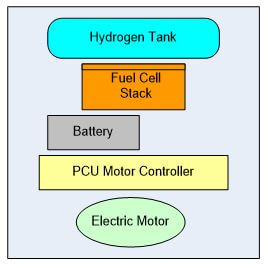

The main components of a fuel cell system are shown in Figure 1. The operating temperature of the fuel cell stack for an automobile range from 60 to 80 ºC. Operating temperatures above 100 ºC would improve the heat transfer and simplify stack cooling, but most automotive fuel cells use PEMFCs or DMFCs, which have a polymer membrane, which limits the operation to temperatures below 100 ºC.

Figure 1. A hydrogen-fueled fuel cell vehicle.

An automotive fuel cell system can use a variety of fuels, and the selection of a fuel depends on factors such as the fuel supply infrastructure, the cost of fuel, the complexity and cost of storage, safety, environmental implications, and the national energy policy. The proper storage of hydrogen is critical for the mass commercialization of fuel cell vehicles. Hydrogen can be stored in many forms, such as compressed gas, liquid, or as metal hydrides. Tanks that hold compressed gases are large and bulky. The average fuel efficiency of new cars is between 20 and 30 mpg; European and Japanese cars average even less. Current vehicles hold 10 to 16 gallons of gasoline, or 30 to 45 liters of space. Since hydrogen has twice the efficiency of gasoline vehicles, they can theoretically store between 5 to 8 kg of hydrogen, which is equivalent to between 200 and 400 L—a sizable reduction in the space needed for fuel. Liquid hydrogen tanks are less bulky but must be stored at extremely low temperatures.

Certain automobile manufacturers have resorted to using other fuels for fuel cells, but most manufacturers still choose pure hydrogen as the option for the future. Another option for hydrogen is the onboard reforming of various fuels or directly feeding various fuel types into the fuel cell. Onboard reforming may eliminate the problem of onboard storage and the lack of hydrogen infrastructure. However, fuel cell vehicles with onboard processors present several issues:

• The vehicles do not have zero emissions.

• Reformed hydrogen is not pure, and therefore decreases the fuel cell’s efficiency.

• Onboard reforming increases the complexity, size, weight, and cost of the entire system.

• The long-term effects of fuel impurities on the fuel cell stack.

There are several companies that are currently working on home hydrogen generation stations based upon solar power, wind turbines, or biofuel. These low-emission methods of generating hydrogen are preferred over the traditional methods of creating hydrogen – which generate various degrees of pollution. Ultimately, the goal is to use hydrogen from non-polluting sources such as chemical reactions, solar panels + electrolysis, or wind power + electrolysis.

Most automobile manufacturers have been developing fuel cell vehicles for at least a couple of decades and have demonstrated at least one prototype vehicle. These auto companies demonstrated their first fuel cell vehicle prototypes in the late 1990s. Commercial FCVs use compressed hydrogen, although many manufacturers also demonstrated a fuel cell vehicle with an alternative fuel type such as methanol. General Motors, Toyota, and Honda have developed their own fuel cell stacks for their fuel cell vehicles. Other automobile manufacturers such as Ford, Mazda, DaimlerChrysler, Mazda, Hyundai, Fiat, and Volkswagen purchased their fuel cell stacks from fuel cell manufacturing companies such as Ballard. From 2008 to 2014, over 20 types of fuel cell cars were released in small quantities, including the Honda FCX Clarity, GM Hydrogen4, and the Mercedes-Benz F-Cell. These vehicles were only released in California, New York, Japan, and Europe.

Table 1 shows a summary of the fuel cell vehicles currently in production and available commercially. The first commercial hydrogen fuel cell vehicle was the Hyundai Tucson FCEV, which was introduced in 2013. In 2015, Toyota introduced the Toyota Mirai in the U.S., Japan, and Europe. The Honda Clarity FCV began to be sold in California in 2016. As shown in Table 1, it has the highest EPA driving range rating of any zero-emissions vehicle in the U.S., with a combined city/highway rating of 67 miles per gallon gasoline equivalent (MPGe).

| Vehicle | Production |

Combined Fuel Economy |

Range | Availability |

| Toyota Mirai | 2015 - present | 66 mpg-e | 312 mi (502 km) | Sold and leased in Japan, California, Europe, Québec and United Arab Emirates. |

| Honda Clarity | 2016 - present | 67 mpg-e | 366 mi (589 km) | Leased in Japan, Southern California, Europe. |

| Hyundai Tucson Fuel Cell | 2014 - present | 49 mpg-e | 265 mi (426 km) | Leased in South Korea, California, Europe and Vancouver. |

Table 1. Fuel Cell Vehicles Available Commercially.

Although considerable efforts have been spent on automotive fuel cells, major challenges still need to be addressed before fuel cell vehicles can be massed produced. Some of these challenges include:

• New techniques, mass fabrication methods, and materials need to be created to lower the cost of producing fuel cells.

• If fuels other than hydrogen are used, CO poisoning of the catalyst may become an issue. The catalyst may need to be replaced or refreshed over time.

• The size and weight of the fuel tanks.

• The lack of sufficient hydrogen infrastructure.

The largest obstacle in the introduction of fuel cell vehicles is the lack of hydrogen infrastructure. Establishing a new fuel infrastructure is extremely costly (but not any costlier than establishing a methanol or ethanol infrastructure). There are, however, already over 150 hydrogen refueling stations around the world. As shown in Table 2, Japan is leading the world with the number of hydrogen gas stations with 100, followed by the United States with 44. Hydrogen that is produced from natural gas can be cheaper than gasoline. Hydrogen produced from water and electricity via hydrolysis is more expensive than gasoline using conventional methods, unless low-cost off-peak electricity is used, or solar panels are employed.

| Country | Number of Stations |

| United States | 44 |

| Canada | 5 |

| Japan | 100 |

| South Korea | 11 |

| Denmark | 6 |

| Finland | 3 |

| Germany | 15 |

| Iceland | 1 |

| Italy | 1 |

| Netherlands | 3 |

| Norway | 1 |

| Turkey | 1 |

| United Kingdom | 6 |

Table 2. Hydrogen Refilling Stations Around the World.

Many of these countries currently have goals to rapidly increase the number of hydrogen gas stations in their country by the year 2020.

Fuel cell vehicles have made a lot of progress during the last couple of decades, and the progress seems to be increasing again to interest from various governments. To be a desirable power source for the future, improvements should continue to be made to the fuel cell stack and manufacturing processes, as well as in the creation of a non-polluting source of hydrogen that can preferably be created in-situ or close to where it will be used.

Posted by

Posted by

Enter the code in the box below: