CT GDL240

CT GDL240 is a carbon paper with a Microporous Layer (MPL). It has a total thickness of 240 um (microns). CT is a great low-cost alternative to conventional carbon paper Gas Diffusion Layer (GDL) materials.

CT GDL240 is available in 20 x 20 cm or 40 x 40 cm sheets at this time.

- Heat transfer during cell operation

- Automated QC inspection system

- Keep some water on the surface for conductivity

- Avoid “flooding”

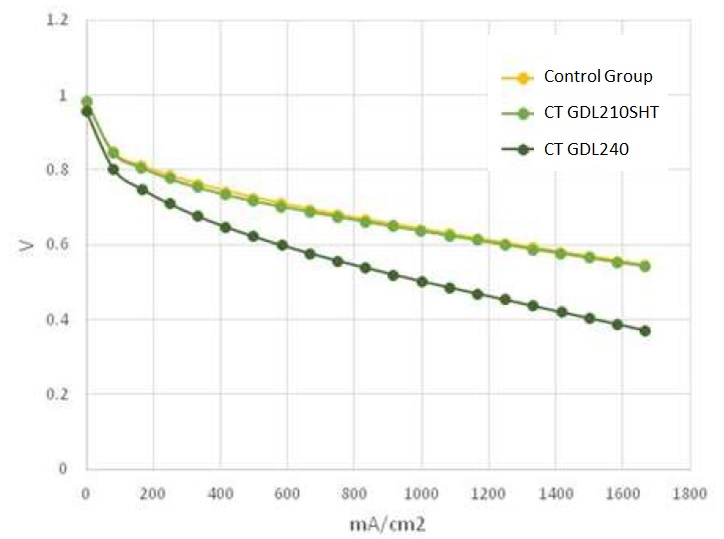

- Active area: 300 cm2

- Anode Fuel: H2

- Anode flow rate (constant flow): Undisclosed

- Cathode Fuel: Air

- Cathode flow rate (constant flow): Undisclosed

- Anode/Cathode Humidification Temperature: 65 C

- Fuel/Oxidant Reactant Relative Humidity: 90%

- Fuel Cell Temperature: 60 C

- Back pressure: None

- Gasket Height: Undisclosed

- MEA Type: Undisclosed

- Anode side catalyst loading: Undisclosed

- Cathode side catalyst loading: Undisclosed

- Anode/Cathode Gas Diffusion Layers: CT GDL210SHT, CT GDL240, and Control Group

An article by Duong et al. entitled "Improving the Immobilization of Glucose Oxidase on Carbon Cloth Via a Hybrid Approach of Cross-Linked Chitosan/TPP Matrices with Na Polymers for High-Performance Self-Pumping Enzyme-Based Biofuel Cells" describes the use of CeTech's carbon cloth based GDL for glucose oxidation immobilization and its use in enzymatic bio-fuel cells.

An article by Yang et al. entitled "Carbon cloth based on PAN carbon fiber practicability for PEMFC applications" describes the use of CeTech's carbon cloth based GDL for PEM fuel cell electrode fabrication and also its electrochemical performance in a single cell hardware with current densities exceeding 1600 mA/cm2 values using H2/Air as the reactants.

An article by Hung et al. entitled "Ultra thin gas diffusion layer development for PEMFC" describes the use of CeTech's carbon cloth and carbon paper production methods for synthesis of an ultra-thing GDL and its single cell performance in a PEMFC hardware and exceeding current densities exceeding 1600 mA/cm2 values using H2/Air as the reactants.

An article by Truong et al. entitled "Functionalized Carbon Black Supported Silver (Ag/C) Catalysts in Cathode Electrode for Alkaline Anion Exchange Membrane Fuel Cells" describes the use of CeTech's carbon paper based GDL for AEMFC application and its single cell performance and exceeding current densities exceeding 500 mA/cm2 values using H2/O2 as the reactants.

An article by Truong et al. entitled "Comparison of Carbon Supports in Anion Exchange Membrane Fuel Cells" describes the use of CeTech's carbon paper based GDL for AEMFC application and its single cell performance and exceeding current densities exceeding 1200 mA/cm2 values using H2/O2 as the reactants using different cathode catalysts for improved ORR.

An article by Truong et al. entitled "Effect of Gas Diffusion Layer Thickness on the Performance of Anion Exchange Membrane Fuel Cells" describes the use of CeTech's carbon paper GDLs for AEMFC application and its single cell performance and exceeding current densities exceeding 2000 mA/cm2 values using H2/O2 as the reactants.

An article by Duong et al. entitled "Development of a facile and low-cost chitosan-modified carbon cloth for efficient self-pumping enzymatic biofuel cells" describes the use of CeTech's carbon cloth based GDLs for enzymatic bio-fuel cell applications.

This Product Related Other Notes:

| Gas Diffusion Layer Properties | |

| Material Type | Carbon Fiber Paper |

| Thickness | 0.24 mm (240 microns) |

| Basic Weight (g/m²) | 90 |

| Air Permeability (s) | < 85 |

| Electrical Resistivity (through plane) | < 15 mΩcm² |

| Tensile Strength | MD: 30 N/cm and XD: 18 N/cm |

| Flexural Modulus (MPa) | MD: 4000 MPa and XD: 1500 MPa |

| Substrate PTFE Treatment | Yes |

| Microporous Layer | Yes |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: