GDL Variety Kit for CO2 Reduction

This product is temporarily unavailable.

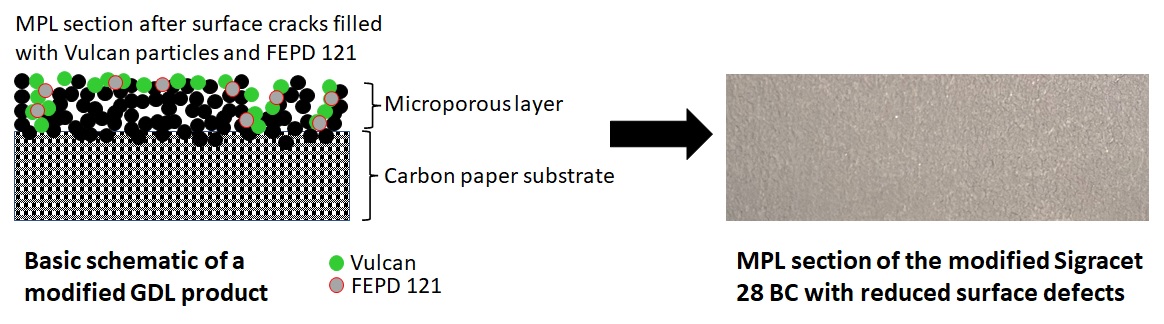

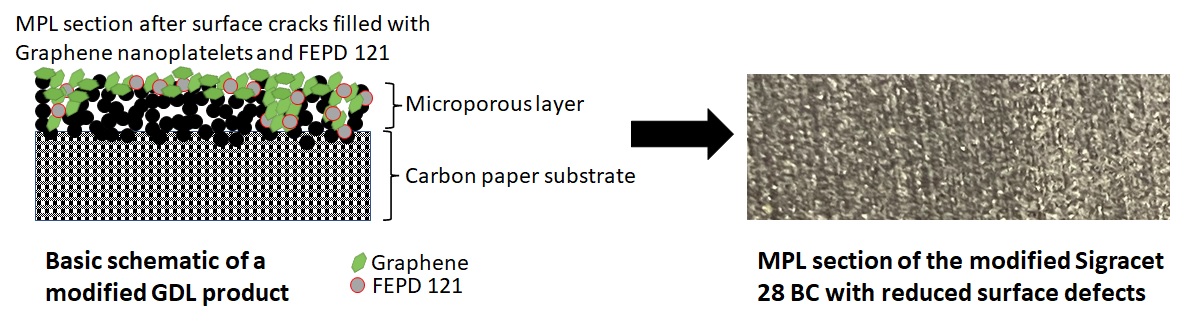

Electrochemical reduction of CO2 (carbon dioxide) to valuable products such as carbon monoxide, hydrocarbons, alcohols, and acids require a novel gas diffusion layer. This should minimize the electrolyte seepage into the cathode GDL and prevent flooding the catalyst layer in order to yield stable electrochemical operation for the cell. We have recognized there is no commercial Gas Diffusion Layer targeted for electrochemical CO2 reduction, and are happy to offer this GDL as an option. This is a developmental product with improvements based on comments received by researchers worldwide after testing the first generation offering. This GDL is comprised of a hybrid microporous layer, where the surface cracks of the original 28 BC are post-filled with a mixture of carbon or graphene nanoparticles and FEPD 121 as the binding agent.

-SGL 28 BC (no modification, baseline) - 10 x 10cm

-SGL 28 BC with Vulcan or Graphene - 20% FEPD 121 Filler - 10 x 10cm

-SGL 28 BC with Vulcan or Graphene - 30% FEPD 121 Filler - 10 x 10cm

-SGL 28 BC with Vulcan or Graphene - 40% FEPD 121 Filler - 10 x 10cm

-SGL 28 BC with Vulcan or Graphene - 50% FEPD 121 Filler - 10 x 10cm

-SGL 28 BC with Vulcan or Graphene - 60% FEPD 121 Filler - 10 x 10cm

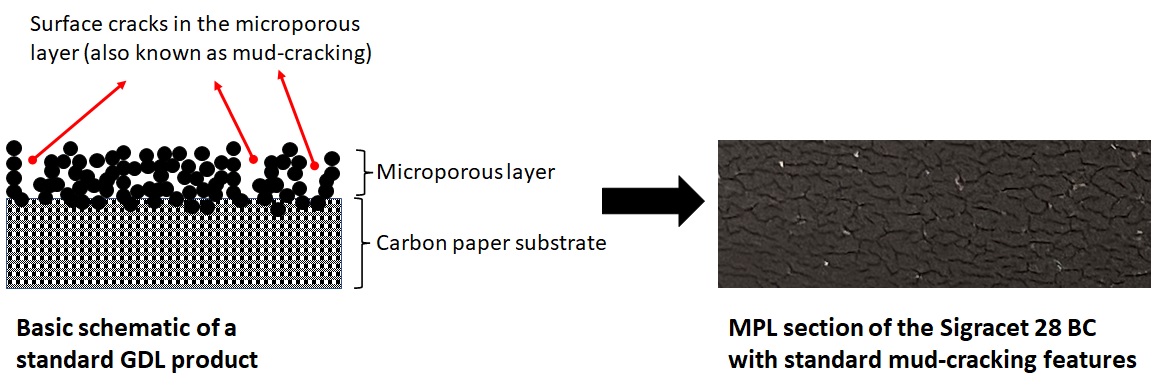

-Presence of surface cracks are identified as a the major issue for electrolyte seepage. This causes H2 generation as a side reaction on the cathode. Teflonization did not create sufficient hydrophobicity of the surface cracks. This observation made it clear the number of surface cracks and their size need to be reduced significantly.

-Electrical conductivity reduction at higher FEPD 121 modification was another observation. A reduction in the through plane electrical conductivity resulted in lower electrochemical performance. This observation made it clear high PTFE coatings (>60 wt%) are undesirable.

Improvement Area #1 for 2nd Generation GDLs: All of the commercial GDLs are manufactured for non-CO2 reduction applications and contain large number of surface cracks. Fuel Cell Store identified a method to fill the surface cracks in order to obtain a microstructure that has fewer surface cracks than the original material. For the 2nd Gen GDL products, the surface cracks have been filled with Vulcan XC-72R or Graphene nanoplatelets with FEPD 121 as the binding agent.

Improvement Area #2 for 2nd Generation GDLs: The amount of FEPD 121 that was mixed with Vulcan XC-72R or Graphene particles was maintained at wt% values in the range of 20 wt% to 60 wt%. This is in order to ensure the new hybrid MPL is highly electrically conductive.

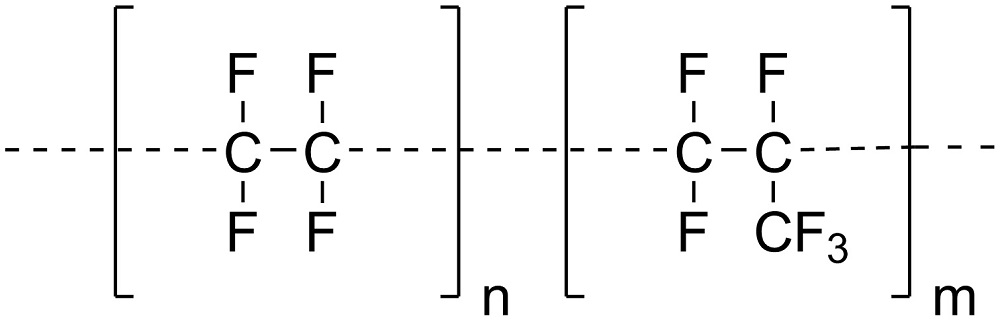

Chemical structure of FEP 121 resin that enables higher degree of hydrophobicity for the new hybrid microporous layer is given below.

The picture below gives a good explanation of how a standard commercial GDL would look like for its microporous layer.

The picture below gives a good explanation of how a modified commercial GDL would look like for its microporous layer for Vulcan - FEPD 121 based filler option:

The picture below gives a good explanation of how a modified commercial GDL would look like for its microporous layer for Graphene - FEPD 121 based filler option:

Since this product category is still developmental, some of the specifications are still undetermined. We welcome the comments/recommendations from our customers in order to further developthe GDL. This developmental GDL for CO2 reduction has not been tested for the stated application due to limited testing capability in our facilities. Fuel Cell Store does not provide any warranties or guarantees for the performance of this GDL variety kit since it is a developmental product.

After identifying a GDL that works well for your from this developmental GDL sample kit, we strongly encourage customers to contact us at sales@fuelcellstore.com and request a quotation for larger size of the product that worked for their research.

| Gas Diffusion Layer Properties | |

| Material Type | Carbon Fiber Paper |

| Thickness | Approximately 240-250 microns |

| Areal Weight | ~ 105 +/- 10 g/m² |

| Bending Stiffness (MD/TD) | Not determined |

| Gas Permeability | Not determined |

| Compressibility | ~ 11% (at 1 MPa) |

| Electrical Resistivity (through plane) | Not determined |

| Roughness (MPL side) | Not determined |

| Impurities (Fe, Co, Ni) | < 10 ppm |

| Tensile Strength | 6.6 / 5.1 MPa (MD/TD) |

| Microporous Layer | Yes, on one side |

| Other Plate Properties | |

| Thermal Conductivity | Not determined |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: