Chlor-alkali Production Membranes

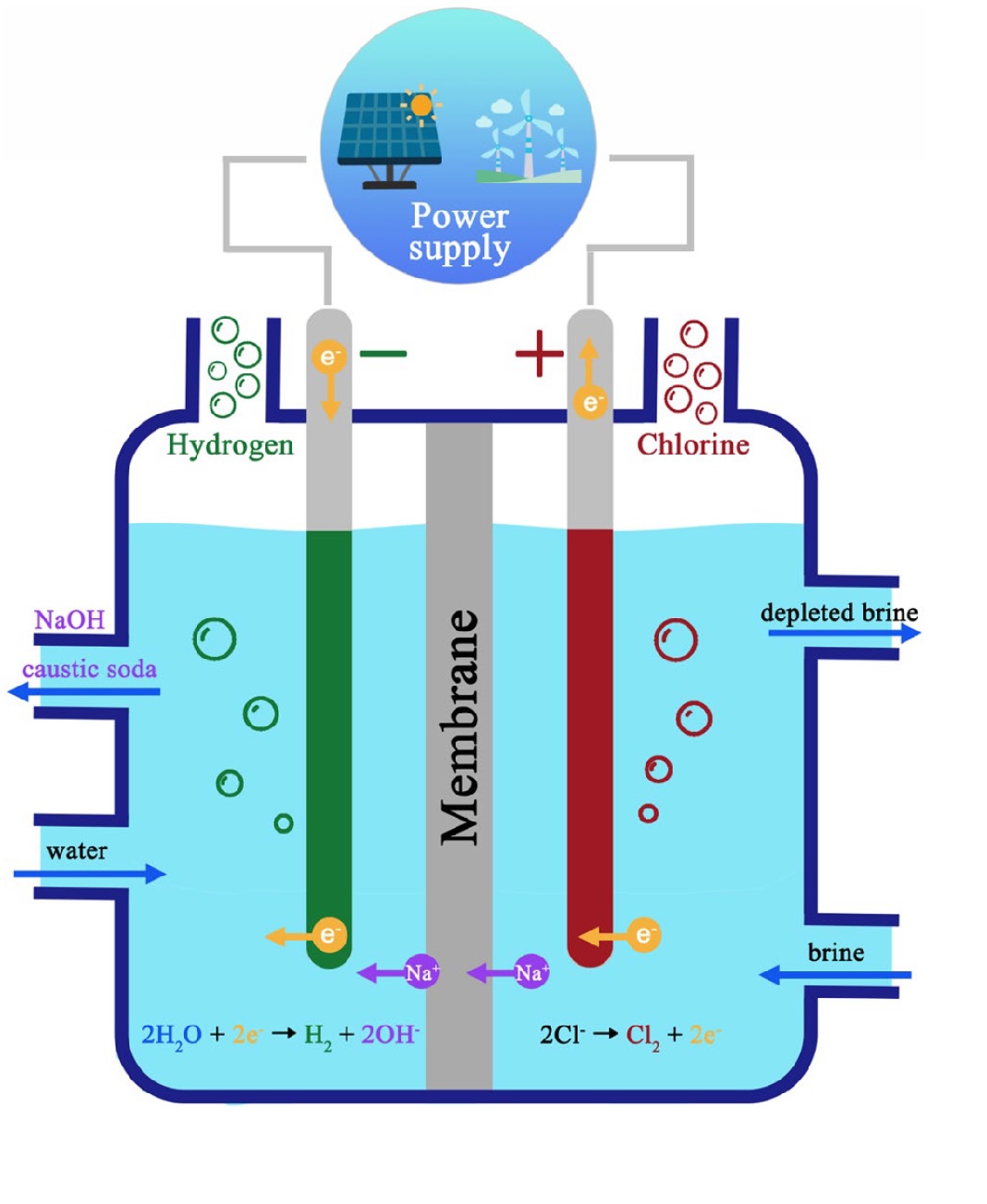

Chlorine (Cl2) and caustic sodium hydroxide (NaOH) are among the most produced commodity chemicals in the world. Modern methods produce Cl2 and NaOH from the electrolysis of brine using a cation exchange membrane between half-cells, which helps chlorine and sodium hydroxide production address the safety concerns of older technologies. A basic schematic of chlor-alkali technology is given on the image provided on the right side (Image Credit: Li et al. Revisiting Chlor-Alkali Electrolyzers: From Materials to Devices). Some of these membranes can also be used for potassium hydroxide (KOH) production too. Fuel Cell Store offers both PTFE fabric reinforced carboxylic acid Nafion membranes and PTFE reinforced sulfonic acid Nafion membranes for this technology for safe and efficient production of chlorine and caustic electrolytes that can be used for various needs or applications.

Chlorine (Cl2) and caustic sodium hydroxide (NaOH) are among the most produced commodity chemicals in the world. Modern methods produce Cl2 and NaOH from the electrolysis of brine using a cation exchange membrane between half-cells, which helps chlorine and sodium hydroxide production address the safety concerns of older technologies. A basic schematic of chlor-alkali technology is given on the image provided on the right side (Image Credit: Li et al. Revisiting Chlor-Alkali Electrolyzers: From Materials to Devices). Some of these membranes can also be used for potassium hydroxide (KOH) production too. Fuel Cell Store offers both PTFE fabric reinforced carboxylic acid Nafion membranes and PTFE reinforced sulfonic acid Nafion membranes for this technology for safe and efficient production of chlorine and caustic electrolytes that can be used for various needs or applications.

Nafion™ membranes are well-suited for industrial use because they tolerate the high temperatures, high electrical currents, and corrosive environment of the electrochemical cells used in this process. These membranes can also be used in the potassium hydroxide process.

✔ Allow cation transfer with minimal electrical resistance

✔ Prevent product gases from mixing

✔ Minimize back transfer of Cl- and OH-

✔ Excellent chlorine oxidation resistance

Some of the other applications that can greatly benefit from this chlor-alkali production membranes are the electroplating (or electrolytic plating), ClO2 (chlorine dioxide) generation, and other similar electrochemical applications.