Aquivion® P98

There is a limited quantity available for this product. Please contact us at sales@fuelcellstore.com to inquire about the availability and pricing.

Aquivion® P98 are perfluorinated pellets in the sulfonyl fluoride (-SO2F) form that exhibit an Equivalent Weight (EW) of 980 g/eq. This material is based on the unique Short Side Chain copolymer of Tetrafluoroethylene (TFE) and Sulfonyl Fluoride Vinyl Ether (SFVE) F2C=CF-O-CF2CF2-SO2F produced by Solvay. The standard form of the sulfonyl fluoride is used to manufacture these pellets and this form is also known as the chemically not stabilized form. Compared to products made with Aquivion® P87S-SO2F pellets (which are chemically stabilized), membrane and dispersion products made with the Aquivion® P98 pellets would have slightly lower lifetime. Chemical stabilization process is also known as end group conversion in which a large amount of polymer end groups are converted to their inert "CF3" configuration, and as such provides excellent lifetime. Chemically stabilized PFSF pellets would yield products (such as membranes, dispersions, etc.) that will exhibit substantially lower fluoride ion release compared to the products are utilizing non-stabilized polymer – a sign of improved chemical durability. Aquivion® P98-SO2F material is based on the unique Short Side Chain copolymer of Tetrafluoroethylene (TFE) and Sulfonyl Fluoride Vinyl Ether (SFVE) F2C=CF-O-CF2CF2-SO2F produced by Solvay.

Aquivion® P98-SO2F resin can be easily melt extruded into a variety of shapes. The extruder should be equipped with a standard three-zone metering screw devoid of barrier or mixing elements. Optimum temperature settings will depend on the configuration of the equipment, but generally range from 200 to 300°C. Optionally, functional groups in the molded part are then hydrolyzed in baths or wet benches with a heated base (NaOH, KOH etc) reaction which may take minutes or hours, depending on thickness and conditions. Aquivion® P98-SO2F can be directly hydrolyzed as described, either completely or only on their outer surface. This will enable functional activity of the sulfonic acid /sulfonyl salt groups for ion-exchange operations or as an acid catalyst.

Like other fluoropolymers, Aquivion PFSF pellets are corrosive in the melt; therefore, all parts having prolonged contact with the melt should be made with corrosion-resistant materials such as Hastelloy®, Inconel®, Monel® or Xaloy®. Chrome or nickel plating is not recommended since they are typically only sufficient for brief processing tests.

• Very high concentration of functional groups for strong proton (or Na+, K+, Li+, etc.) conductivity after the hydrolysis stage

• High softening point for high temperature operation well above 80 ºC for the products utilizing this resin material

• Strong water retention for better fuel cell operation at low-humidity conditions for membranes utilizing this resin material

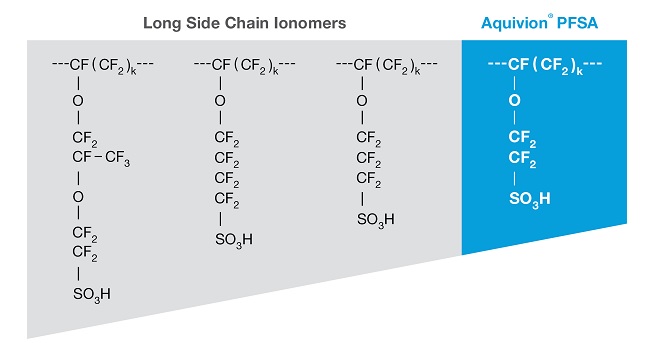

Aquivion® PFSF’s short side chain pellets would enable the synthesis of products (membranes, dispersions, etc.) that have either better mechanical properties at the same IEC (ion-exchange capacity) or a higher IEC at the same mechanical properties than long side chain (LSC) based PFSF pellets. A comparison of Short Side Chain and Long Side Chain PFSA polymers that are manufactured from the corresponding resin materials from a polymeric composition is provided in the following image.

Aquivion® P98-SO2F Technical Data Sheet

Aquivion® P98-SO2F Technical Data Sheet

Properties that are provided on the FuelCellStore website are directly taken from the technical documentation sheets provided by the manufacturer for consideration as "typical properties" and not to be construed as specifications.

A typical lead time of 3-4 weeks is to be expected.

| Solvay Aquivion Pellets | |

| Appearance | Translucent |

| Form | Pellets |

| Melt Mass Flow Rate (270 C) | 5.0 to 20 g/10 min for 2.16 kg batch size (ASTM D1238) |

| Melt Mass Flow Rate (280 C) | 15 to 50 g/10 min for 5.0 kg batch size (ASTM D1238) |

| Density | 2.08 g/cm3 (ASTM D792) |

| Equivalent Weight (EW) | 940 to 1020 g/eq (Internal Method) |

| Melting Temperature | 230 to 250 deg Celsius (ASTM D3418) |

| Crystallization Heat | 8.00 to 10.00 J/g (ASTM D3418) |

| Heat of Fusion | 8.00 to 10.00 J/g (ASTM D3418) |

| Drying Temperature | 105 deg Celsius (Internal Method) |

| Drying Time | 20.0 hr |

| Thermal Resistance | 350 deg Celsius (Internal Method with TGA, in air ramped 10 deg Celsius/min) |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: