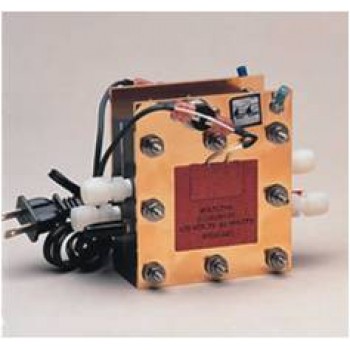

Direct Methanol Fuel Cell Hardware

Direct Methanol Fuel Cell (DMFC) Hardwares apply liquid fuel to the fuel cell to generate power. DMFC involves gas evolution during the electrochemical reaction that greatly influences the performance of the fuel cell. Methanol has more energy in volume compared to hydrogen; and since it can be utilized in a non-compressed state – it has become a fuel of choice for several uses including where size and weight are an issue as well as portability.

These DMFC fuel cell can be taken apart and rebuilt!

The DMFC hardware can also use for Direct Ethanol Fuel Cell (DEFC) and Bio-fuel cell in which liquid fuel is required to be managed to flow through the fuel cell.

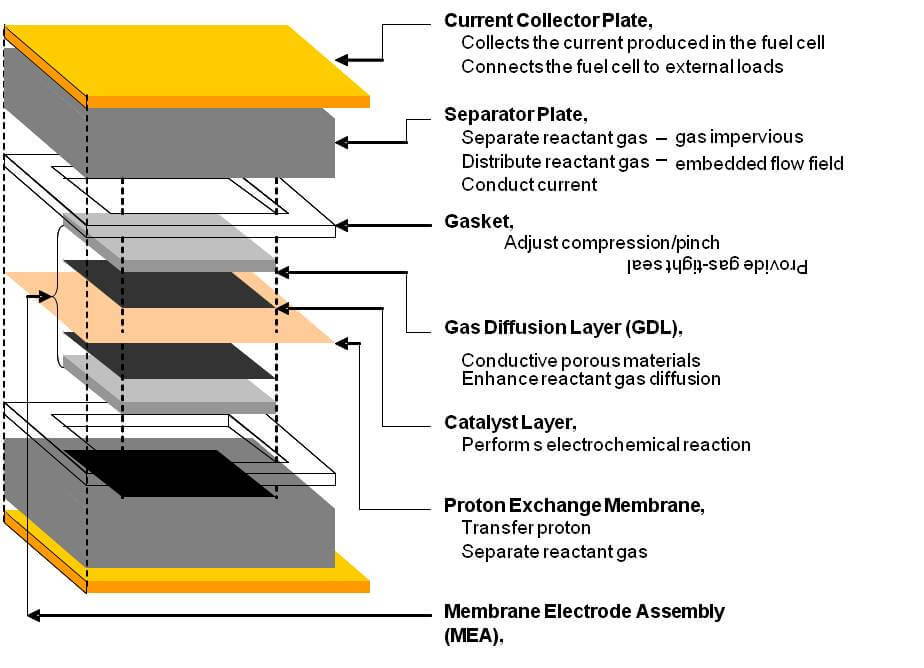

This item includes all the key components to make such reactions occur. It also performs compression of the membrane electrode assembly (MEA) while providing uniform gas distribution and uniform temperature to the cell.

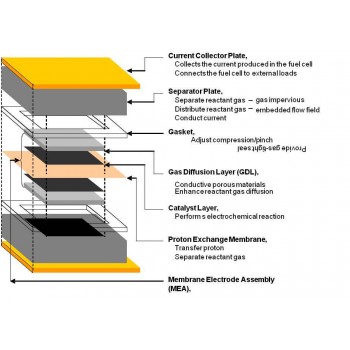

A gold-plated plate serves as current collector plate for the fuel cell. The gold plating provides corrosion protection and good electrical contact with the graphite separator plate. A high purity graphite plate with high electrical conductivity (900 Scm-1) and high thermal conductivity (117 Wm-1K-1) is designed with serpentine gas flow channels and manifold. A Gasket is included to provide a secured seal for the MEA. High power silicon rubber heaters are installed at both ends of the fuel cell to maintain a constant cell temperature.

✔ Machined graphite separator plates with serpentine flow fields

✔ Gold plated current collectors

✔ Banana plugs for monitoring voltage

✔ Belleville washer

✔ Built-in silicon rubber heaters (60 watt) for maintaining cell temperature, with selectable voltages (110 or 220VAC)

✔ Nylon fittings for gas tight connection to 1/4” tubing (for active area sizes of 1, 5, and 25 cm2)

✔ Stainless Steel fittings for gas tight connection to 1/4” tubing (for active area sizes of 50 and 100 cm2)

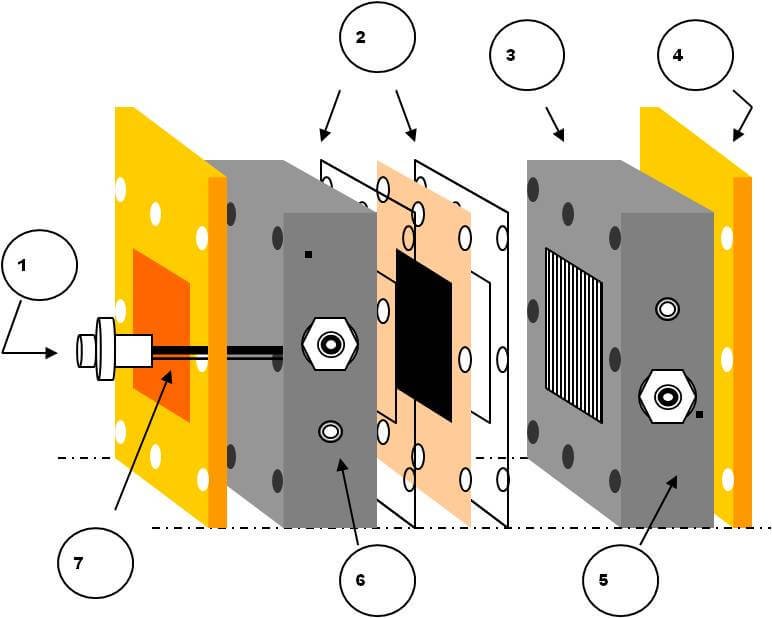

Schematic of the Fuel Cell Hardware's Components:

- Column / Pin Type

- Serpentine

- Straight Channel

General lead time of two weeks to be expected.

1. Through-Bolt Assembly Design

1. Through-Bolt Assembly DesignWrite a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: