Fumasep FAAM-20

Please note that this material is not avilable at this time.

Fumasep FAAM-20 is a non-reinforced microporous separator (also known as separator or diaphragm) with a thickness of 20 µm and high stability in caustic environments and can be used for conventional alkaline electrolyzers that uses caustic solutions. The polymer backbone for this membrane is based on a proprietary hydrocarbon resin and there is no functional groups in this product for the transfer of the hydroxyl ions. A microporous separator is a completely different product than an anion exchange membrane for its working principle.

For the electrochemical operation of an alkaline electrolyzer with a microporous separator, it is required to use highly caustic electrolyte (6M to 12M, where M stands for Molar, a unit of concentration) and have this electrolyte continuously circulated at the anode/cathode compartments. Due to excellent wetting behavior of the highly concentrated alkaline electrolytes, they will be naturally wicked into the micropores of the microporous separator and completely saturating the membrane and then establish an ionic bridge to the opposite side of the membrane as a result of this wicking. In that regard, the higher ionic conductivity of the electrolyte would determine the ionic conductivity of the microporous separator. Anion exchange membranes, on the other hand, do not require the usage of liquid alkaline electrolytes for their operation because there are functional groups that are established on the polymer backbone where hydroxyl ions are transferred with the help of these functional groups across the anion exchange membrane itself. Microporous separators do not have any functional groups such as quaternary ammonium cations and they are completely inert for the aspect of ionic conductivity. It is the electrolyte that wicks into the microporous separator that enables the hydroxyl ion transfer. The main function of the microporous separator for a conventional alkaline electrolyzer is to act as a physical separator component and prevent the generated by-product mixing during the operation of the alkaline electrolyzer cell. While commercial anion exchange membranes can only tolerate to 1M type alkaline electrolytes, microporous separator products can tolerate up to 12M type concentrations. Most anion exchange membranes can only handle low temperatures (up to 55-60 deg Celsius), microporous separator product can be used in the temperature range of room temperature to 100 deg Celsius.

This microporous separator is not suitable for pure water electrolysis applications and it will always require the addition of NaOH or KOH powder into the deionized water or distilled water. Do not use any other water sources such as tap-water or reverse osmosis water when preparing the alkaline electrolyte for this microporous separator.

Fumasep FAAM-20 membrane comes in either a 10cm x 10cm or 20cm x 30cm size sheet.

Fumatech membranes are highly sensitive to differences in humidity and moisture content. Therefore the membranes can vary +/- 0.5cm from the original cut sizes. Also due to this sensitivity the manufacturer expects wrinkles to form, however soaking the membranes in deionized water will return the membranes to the full size planar state according to the manufacturer.

• Applications: Alkaline electrolysis using liquid aqueous KOH (6 - 12 M KOH), preferentially at both, anode and cathode side.

• Anion Exchange Membrane

• Operation Range: 6 - 12 M KOH, temperature RT - 100 °C.

• Thickness (dry): 18 - 22 micrometers (0.70 - 0.86 mil)

• Sizes: 10cm x 10cm, 20cm x 30cm

Fumasep FAAM-20 Technical Specification Sheet

Fumasep FAAM-20 Technical Specification Sheet

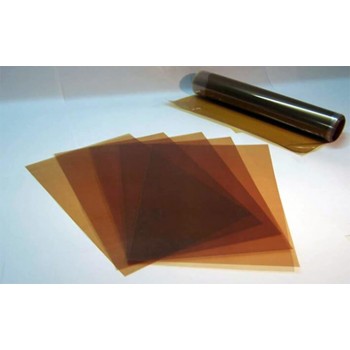

The membrane is the thin brown foil, delivered on a backing foil (colourless rigid PET foil). Pull off carefully the membrane (brown) from the backing foil. The membrane is delivered in dry form.

Keep membrane package closed / sealed when unused. Store, handle and process the membrane in a clean and dust-free area. Always wear protective gloves when handling the membrane. Handle with care, be sure not to puncture, crease or scratch the membrane, otherwise leaks will occur. All surfaces which may get into contact with the membrane during inspection, storage, pretreatment and mounting must be free of sharp edges or angles.

No specific pretreatment required. The membrane is self-activating in the cell after contact with aqueous caustic electrolyte (e.g. 9 M aqueous KOH solution) within several hours.

Depending on cell design, activation may also be done before assembling: Put the membrane sample between stabilizing meshes (in order to avoid curling) in aqueous KOH solution (concentration according to application) for at least 24 hrs at room temperature. Use closed container to avoid CO2 contamination (carbonate formation that may affect conductivity). Membranes must be covered by KOH solution. Membranes will expand when subject to swelling process. The hydration level can be controlled by KOH concentration and temperature, e.g. 9 M KOH solution at room temperature leads to approx. 50 - 70 wt% hydration level.

If you have any concerns about storage, chemical stability, pre-treatment or before proceeding, please feel free to contact us for further information.

Please note that a current lead time of four to six weeks is to be expected.

| Membrane Properties | |

| Membrane | Anion Exchange Membrane |

| Thickness | 18 - 22 µm (microns) |

| Appearance / Color | Brown, Transparent |

| Backing Foil | on PET |

| Delivery Form | Dry |

| Reinforcement | None |

| Counter Ion | None |

| Swelling (hydration) | 40 - 60 wt% (treatment with 12 M aqueous KOH at 20 °C for 1 day) |

| Length Increase | 0 - 2 wt% (treatment with 12 M aqueous KOH at 20 °C for 1 day) |

| Thickness Increase | 25 - 40% (treatment with 12 M aqueous KOH at 20 °C for 1 day) |

| Young’s modulus at 23 °C / 50 % r.h. | > 1000 MPa |

| Temperature durability (dry) | No oxidation below 250 °C |

| pH durability range | stable under highly alkaline conditions |

| Pressure operation | Not tested above 1 bar difference |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: