Fumasep FAPQ-330

Please note that avilable inventory is limited at this time.

Fumasep FAPQ-330 is a fluorinated anion-exchange membrane - non-reinforced with low resistance, high oxidative stability, resistant to chlorine and high stability in acidic environment.

Fumasep FAPQ-330 membrane comes in either a 10cm x 10cm or 20cm x 30cm size sheet.

Fumatech membranes are highly sensitive to differences in humidity and moisture content. Therefore the membranes can vary +/- 0.5cm from the original cut sizes. Also due to this sensitivity the manufacturer expects wrinkles to form, however soaking the membranes in deionized water will return the membranes to the full size planar state according to the manufacturer.

• Applications: Electrochemical processes requiring anion exchange membranes with high oxidative stability and highly resistant to chlorine. Another application that can benefit greatly from this membrane is non-aqueous redox flow batteries that utilize organic solvents such as acetonitrile, etc. The dimension change or swelling of the membrane for non-aqueous redox flow battery applications would predominantly depend on the chemical composition of the electrolyte used. Mechanically reinforced fluorinated anion exchange membranes would demonstrate increased mechanical stability and lower solvent mediated crossover compared to non-reinforced counterparts for non-aqueous redox flow battery applications.

• Type: Anion Exchange Membrane

• Operation Range: Acidic environment pH < 4, at pH > 6 the material has low ionic conductivity. The material is not stable in caustic environment (pH > 9). General temperature range is room temperature to 50 °C.

• Thickness (dry): 25 – 35 micrometers (0.98 - 1.37 mil)

• Sizes: 10cm x 10cm, 20cm x 30cm

Fumasep FAPQ-330 Technical Specification Sheet

Fumasep FAPQ-330 Technical Specification Sheet

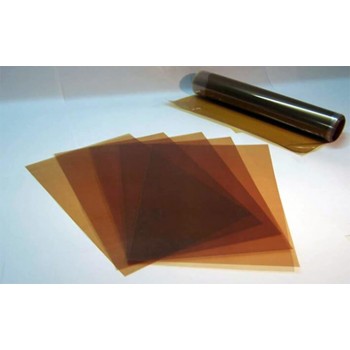

The membrane is the slightly opaque foil, delivered on a backing layer (colourless rigid PET foil). Peel off carefully the membrane from the backing layer. The membrane is ready to use.

Keep membrane package closed / sealed when unused. Store, handle and process the membrane in a clean and dust-free area. Use only new and sharp knives or blades, when cutting the membrane. Always wear protective gloves when handling the membrane. Handle with care, be sure not to puncture, crease or scratch the membrane, otherwise leaks will occur. All surfaces in contact with the membrane during handling, inspection, storage and mounting must be smooth and free of sharp projections.

The membrane is delivered in dry form. No pretreatment is required. If additional cleaning is required rinse the membrane in either the application solution or deionized water according to the application requirement. However, membranes will expand and contract based on electrolyte content. If you have any concerns about storage, chemical stability, and pretreatment please feel free to contact us for further information.

Please note that a current lead time of four to six weeks is to be expected.

| Membrane Properties | |

| Membrane | Anion Exchange Membrane |

| Thickness | 25 – 35 µm (microns) |

| Appearance / Color | Slightly Opaque |

| Backing Foil | PET |

| Delivery Form | Dry |

| Reinforcement | None |

| Counter Ion | Chloride / Methylsulfate |

| Weight Per Unit Area | 4.0 – 5.0 mg cm^-2 |

| Area Specific Resistance (ohm cm²) | < 0.35 (0.5 M H2SO4) |

| Selectivity | > 85% (0.1 / 0.5 mol/kg KCl at T = 25 °C) |

| Proton Transfer Rate | > 5.500 μmol min^- 1 c m^-2 |

| Tensile Strength - max. (MPa) | 20 – 45 MPa |

| Yield Strength at 23°C / 50 % R.H. | 20 – 35 MPa |

| Young’s modulus at 23 °C / 50 % r.h. | 600 – 1200 MPa |

| Elongation to Break (%) | 150 – 250 |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: