Protium-300

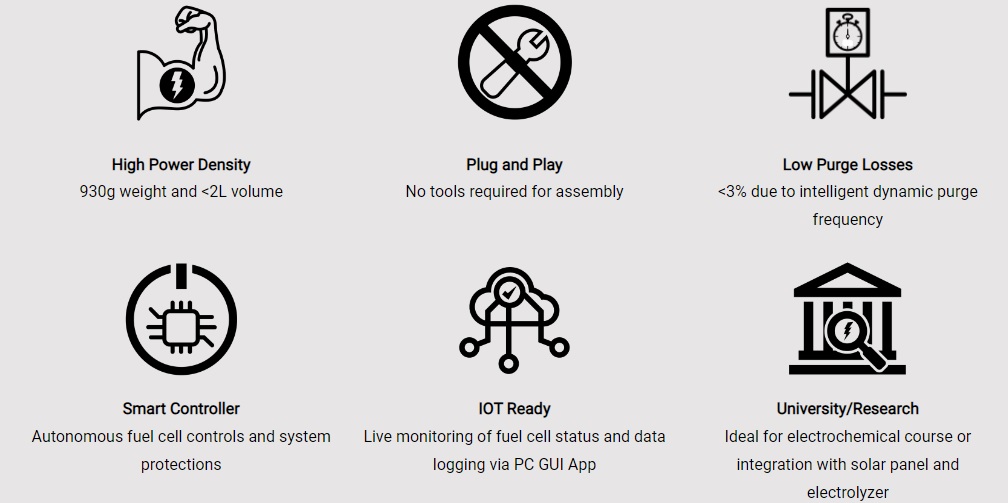

The Protium-300 is an advanced hydrogen PEM fuel cell that is designed for tomorrow's unmanned vehicles. The Protium Series is the flagship suite of fuel cell systems and the culmination of more than a decade of cutting edge R&D. Every Protium fuel cell is made of the best quality membrane electrode assemblies to ensure the highest power output in the smallest form factor.

✔ 40-cell graphite plate fuel cell stack with cell voltage monitoring ports

✔ Electronic controller

✔ Heat management system (cooling fan with integrated pwm control)

✔ Fuel supply system (solenoid valves, gas pressure sensor, gas tubing and connector)

✔ On-off push button with status LED

✔ Power/signal cable

✔ RS232 to USB cable

✔ Factory Acceptance Tests (FAT) report

✔ Pelican storage case

• Rated Power: 300W

• Rated Current: 12.5A

• Voltage Output: 24-36V DC

• Start-up Time: 5s

• Operating Ambient Temp.: 0 - 40 °C

• Fuel Cell Weight: 930g

• Fuel Cell Dimensions: 195 x 113 x 87 mm

• Electronic Controller: FLY 3.0

• Electronic Controller Weight: 240g

• Electronic Controller Dimensions: 127 x 90 x 62 mm

• Hydrogen Gas: Dry, 99.999% purity

• Delivery Pressure: 0.4-0.7 bar (6-10 psig)

• Fuel Consumption: 3.8L/min @ 300W

• Gas Tubing: PU, 4 mm OD

• Supply & Purge Control: Solenoid valves with integrated pressure sensor

• Processor Board: FLY V3.0

• Electronic Controller Dimensions: 127 x 90 x 62 mm

• Electronic Controller Weight: 240g

• Output Connector: Please see the Protium-300 User Manual for this.

• Warning & Protections: Low voltage, high temperature, low battery, low fuel

• Communication: RS-232/USB

• Data Acquisition (DAQ) Software: PC graphic user interface (GUI) application

• GUI Capabilities: Live monitoring, graph plotting, data logging, snapshot

This fuel cell system requires the use of 6S LiPo battery (>100C discharge rated). The ultra-lightweight feature of Protium-300 fuel cell system comes from the elimination of bulky and heavy external humidifiers needed for PEM fuel cell technology. An automated fuel cell stack conditioning protocol maintains the hydration of the membrane. During the stack conditioning event, fuel cell system briefly gets disconnected from the load (approximately 100 milliseconds). A small LiPo battery needs to be used to provide electrical energy to the load during the stack conditioning event.

The ultra-lightweight Protium-300 fuel cell system works in tandem with the Hybrid LiPo battery. During the startup of the fuel cell, the Hybrid LiPo battery provides the electrical energy to initialize all the electronics. For the power demand up to 300 W, the electrical energy is solely supplied by the fuel cell stack. For events such as take off and emergencies that demand more than 300 W for short durations, LiPo battery provides all the electrical energy needed. For the most efficient use of this tandem power architecture, it is suggested that fuel cell stack to be used for cruising part of the flight and Hybrid LiPo battery to be used during take-off and short duration emergencies.

![]() Protium-300 GUI Installer User Guide

Protium-300 GUI Installer User Guide

Typical lead time of 6 - 8 weeks to be expected.

| Fuel Cell Properties | |

| Rated Power | 300W (12.5A @ 24V) |

| Operating Temperature | 1 - 40 ºC |

| Electronic Controller | FLY driver board version 3.0 |

| Flowfield Type | S-flow technology |

| Hydrogen Max Consumption | 3.8 L/min @ 300W |

| Hydrogen Pressure | 0.4-0.7 bar (6-10psig) - Delivery pressure |

| Cooling | 2x 12V fan, pwm controlled |

| Voltage Range | 24- 36V |

| Hydrogen Purity Requirement | Dry, 99.999% purity |

| Gas Tubing Requirement | PU, 4mm OD |

| Start up time | 5 s |

| Efficiency of System | 48% (based on LHV of H2) |

| Supply & Purge Control | Solenoid valves |

| Type of Fuel Cell | PEM, 40 cells |

| Low voltage shut down | 20 V |

| Suggested Hybrid LiPo Battery | 6S configuration (>100C discharge rated) |

| Low Battery Warning | <21 V |

| Data Acquisition, Graphic User Interface | RS232/USB |

| Low Hydrogen Shutdown | <0.2 bar |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below:

Protium-300 VI Curve

Protium-300 VI Curve