QL-1000 PEM Hydrogen Generator

QL Hydrogen Generator is used to generate up to 99.9995% purity hydrogen by world advanced PEM technology. The product hydrogen can be used for for gas chromatography (GC) carrier gas and fuel gas, ICP-MS collision gas, hydrogenation reactor, fuel cell, and emissions test equipment. It is the ideal equipment to replace regular gas cylinders in the laboratory. The QL Hydrogen Generator is the solution of choice for on-site gas production.

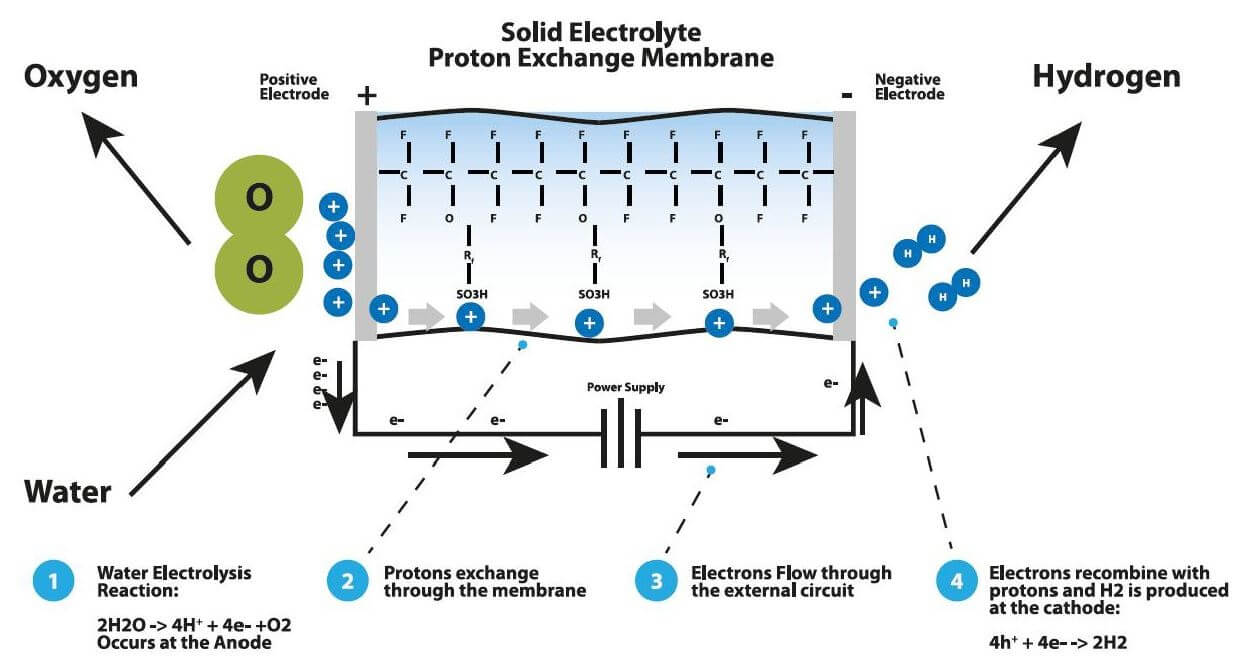

QL Hydrogen Generation systems use a platinum catalyst and PEM (Proton Exchange Membrane)technology to split deionized water into its constituent parts. The proton exchange membrane (PEM) only allows water and positive ions to cross between compartments. The membrane also serves as the electrolyte in the cell, eliminating the need for hazardous liquid electrolytes such as concentrated potassium hydroxide. PEM water electrolysis simply splits pure deionized water (H2O) into its constituent parts, hydrogen (H2) and oxygen (O2), on either side of the membrane.

When a DC voltage is applied to the electrolyzer, water is fed to the anode or oxygen electrode and are oxidized to oxygen and protons, while electrons are released. The protons (H+ ions) pass through the PEM to the cathode, or hydrogen electrode, where they meet electrons from the other side of the circuit and are reduced to hydrogen gas. The two reactions that occur in the cell are as follows:

1. 2H2O -> 4H+ + 4e- +O2

2. 4H+ + 4e- -> 2H2

Thus, the only possible components of the streams are hydrogen, oxygen and water moisture.

• Gas chromatography carrier gas and fuel gas

• Hydrogen supply for fuel cell

• ICP-MS collision gas

• Hydrogen supply for hydrogenation reactor

• Hydrogen supply for emissions test equipment

• Gas analyzer support gas

• ELCD (conductivity detector) reaction gas

• AED (atomic emission detector) of reaction gas

• Other pure hydrogen application field

• Solid polymer electrolyte technology

• Plural electrode and multi-unit electrolysis cell structure

• Electrolysis of pure water (no adding alkali)

• Lower power consumption

• Low cell voltage

• High electrolysis efficiency

| Model | Unit | QL-150 | QL-300 | QL-500 | QL-1000 | QL-2000 |

| H2 Flow Rate | cc / min | 0 - 150 | 0 - 300 | 0 - 500 | 0 - 1000 | 0 - 2000 |

| H2 Purity | % | > 99.9995 | ||||

| Output Pressure | bar | 0.2 - 4.0 | ||||

| Dew Point | ° C | - 65.0 | ||||

| Input Power | Watt | < 90 | < 150 | < 300 | < 500 | < 1000 |

| Voltage | AC | 220V/110V, 50-60Hz | ||||

| Water Tank Capacity | Liter | 3.0 | 3.0 | 3.0 | 6.0 | 6.0 |

| Operating Environment | Indoor | 5° C to 45° C, < 80% Room Humidity | ||||

| Weight | kg | < 15 | < 15 | < 15 | < 27 | < 30 |

| Water Resistivity | MΩ*cm | > 1 | ||||

| Dimensions (L x W x H) | mm | 420 x 227 x 352 | 420 x 227 x 352 | 420 x 227 x 352 | 485 x 368 x 352 | 505 x 368 x 352 |

| Membrane | Nafion PFSA membrane | |||||

General lead time of two to three weeks to be expected.

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below:

QL-1000 PEM Hydrogen Generator Manual

QL-1000 PEM Hydrogen Generator Manual