Aquivion® E98-09S

Production of this membrane has been postponed until further notice.

Aquivion® membrane is used to separate the anode and cathode compartment of proton exchange membrane fuel cells (PEMFCs) and water electrolyzers, separators for electrochemical hydrogen pump or redox flow batteries, and pervaporation or gas humidification systems. Various other electrochemical technologies can also benefit from Aquivion® membranes. Aquivion® E98-09S membrane has a nominal thickness of 90-115 micrometers (≈ 3.5-4.5 mil), which makes it suitable for unpressurized or pressurized H2/Air PEMFCs, unpressurized or pressurized H2/O2 PEMFCs, unpressurized or pressurized water electrolyzers, unpressurized or pressurized electrochemical hydrogen pumps, redox flow batteries, pervaporation or gas humidification systems, etc. Direct methanol fuel cells (DMFCs), direct ethanol fuel cells (DEFCs), and various other alcohol based fuel cells can also benefit greatly from this cation exchange membrane. This membrane is supplied bare, with no backing plastics on either side.

Solvay Aquivion® E98-09S is a perfluorosulfonic acid (PFSA) ionomer membrane that exhibits an equivalent weight (EW) of 980 g/eg. Aquivion® PFSA ionomer membranes are melt-extruded products based on the unique Short Side Chain copolymer of Tetrafluoroethylene (TFE) and Sulfonyl Fluoride Vinyl Ether (SFVE) F2C=CF-O-CF2CF2-SO2F produced by Solvay. This membrane is available in the acid form (H+) and features a lower EW than most commercial proton exchange membranes or cation exchange membranes. The unique Short Side Chain copolymer allows higher crystallinity, improved mechanical properties, and better proton conductivity. Aquivion® E98-09S membrane is a non-reinforced membrane based on the chemically stabilized Solvay PFSA ionomer, which exhibit substantially lower fluoride ion release compared to the non-stabilized polymer – a sign of improved chemical durability. Chemical stabilization process is also known as end group conversion in which a large amount of polymer end groups are converted to their inert "CF3" configuration, and as such provides excellent lifetime. Aquivion® membranes are also manufactured in the standard form without the chemical stabilization. The polymer is chemically resistant and durable for various electrochemical and non-electrochemical applications.

• Very high concentration of functional groups for strong proton (or Na+, K+, Li+, etc.) conductivity

• High softening point for high temperature operation well above 80 ºC

• Strong water retention for better fuel cell operation at low-humidity conditions

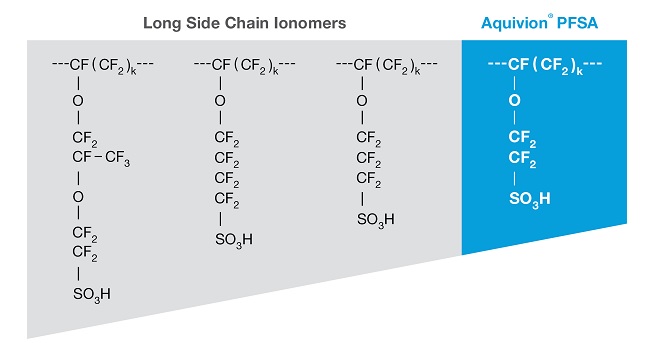

Aquivion® PFSA’s shorter side chain makes it possible to achieve either better mechanical properties at the same IEC (ion-exchange capacity) or a higher IEC at the same mechanical properties than long side chain polymers (LSC). A comparison of Short Side Chain and Long Side Chain PFSA polymers from a polymeric composition is provided in the following image.

Aquivion® E98-09S Technical Data Sheet

Aquivion® E98-09S Technical Data Sheet

Properties that are provided on the FuelCellStore website are directly taken from the technical documentation sheets provided by the manufacturer for consideration as "typical properties" and not to be construed as specifications.

| Membrane Properties | |

| Thickness | 90 micrometers +/- 20 micrometers (or 3.5-4.5 mils) |

| Density | 1.93 g/cm3 (at 23 deg Celsius and 50% RH. Internal Method.) |

| Weight Per Unit Area | 174 g/m2 |

| Equivalent Weight (EW) | 980 g/eq (Internal Method) |

| Conductivity (mS/cm) | Greater than 160 mS/cm (Internal Method) |

| Total Acid Capacity (meq/g) | greater than 1.00 meq/g (Internal Method) |

| Water uptake (wt%) | Less than 30% (4 hours of soak in liquid H2O @ 100 deg Celsius. Internal Method.) |

| Tensile Modulus | 270 MPa (Internal Method) |

| Tensile Stress (MD: Break) | 40 MPa (ASTM D882) |

| Tensile Stress (TD: Break) | 30 MPa (ASTM D882) |

| Elongation % in liquid H2O (MD) | Less than 12% (Internal Method) |

| Elongation % in liquid H2O (TD) | Less than 20% (Internal Method) |

| Elongation (MD: Break) | 150% (ASTM D882) |

| Elongation (TD: Break) | 200% (ASTM D882) |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: