ELAT LT1400

FuelCellsEtc's ELAT® LT1400 is a carbon cloth Gas Diffusion Layer (GDL) with a carbon microporous layer. ELAT has been engineered to have state-of-the-art performance over a wide range of operating conditions. Thickness is 454 um.

Gaseous reactant consuming electrochemical devices require the fuel or oxidant species to reach to the anode or cathode electrocatalyst layers in an evenly distributed fashion. Additionally, if the electrochemical device needs to consume a liquid reactant in a controlled fashion (meaning limiting the quantity of the liquid medium arriving to the catalyst layer), then there is a need for Teflonization both at the substrate fabric and MPL sections. ELAT - LT1400 gas diffusion layer is comprised of base fabric (also known as substrate) and MPL. Having the Teflonization treatment both at the base fabric and MPL sections provides unique features. Teflonization improves the water management aspect of the electrochemical device if the reactant species are in the gaseous form. MPL is comprised of carbon black and PTFE and it provides cushioning effect for the membrane and protects it from being damaged by the long carbon fibers present in the base fabric. Having the micro-porous and macro-porous features within the MPL and base fabric improves the even distribution of the gaseous species across the entire active area.

If ELAT – LT1400 is used with liquid reactant consuming electrochemical devices, the presence of Teflon limits how fast the electrocatalyst layer being flooded by the liquid medium. For example, for direct methanol fuel cells, it is essential that hydrophobicity of MPL and base fabric restrict how much methanol/water is arriving to the anode electrocatalyst layer and hence getting close to the membrane. With the proper Teflonization, the fuel crossover issues can potentially be minimized to a certain extent.

The above-mentioned features make ELAT – LT1400 ideally suitable for gaseous reactant consuming electrochemical devices (such as hydrogen/air fuel cells, hydrogen/oxygen fuel cells, etc.), gas generating electrochemical devices (such as cathode side of the PEM or alkaline electrolyzers, etc.), direct methanol fuel cells, batteries, and various other electrochemical devices.

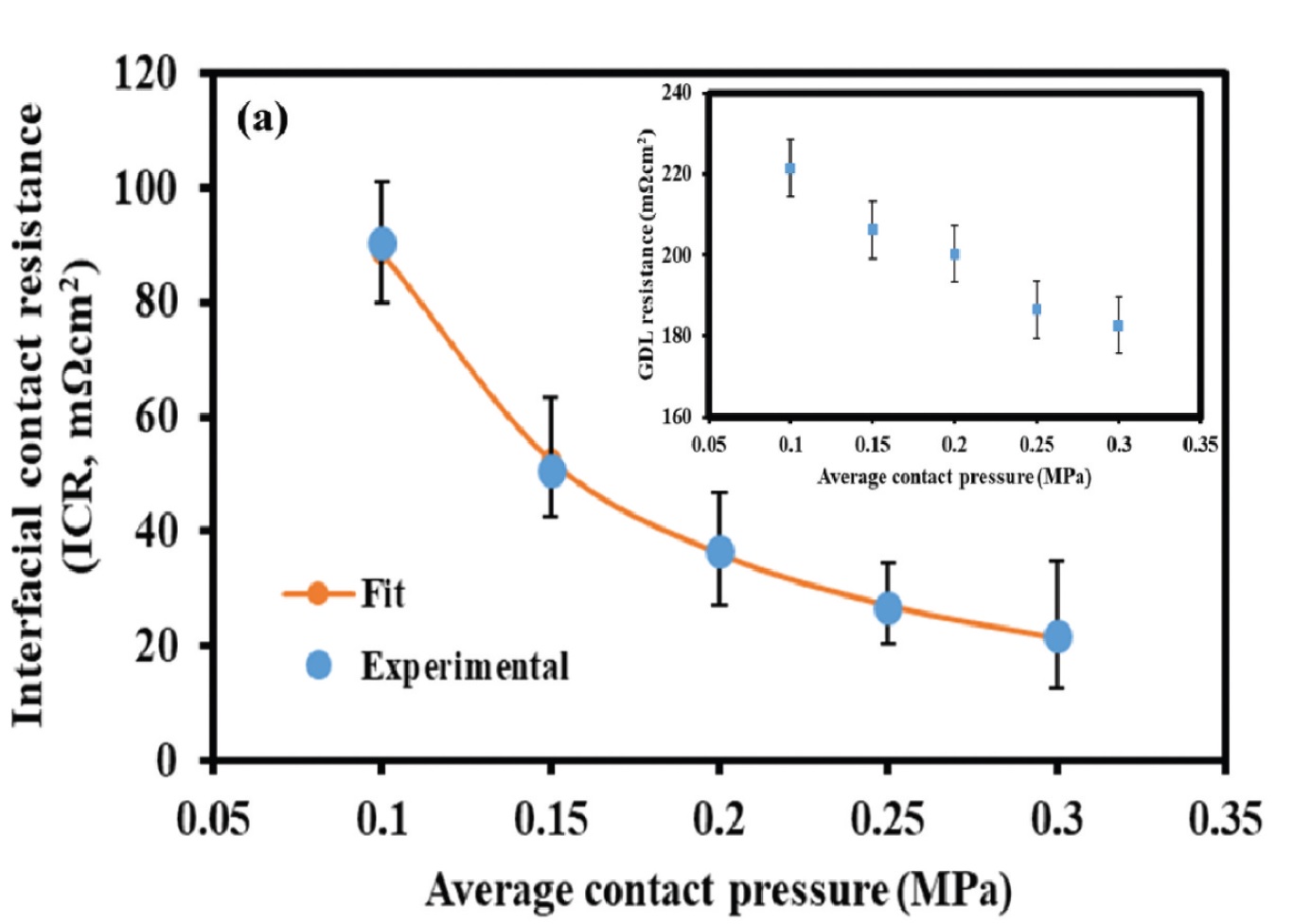

The graph below provides the interfacial contact resistance of ELAT LT1400 at different contact pressure values (Credit: Amit C. Bhosale et al. in the article entitled "Effect of gas pressure and clamping pressure on interfacial contact resistance of a cylindrical polymer membrane fuel cell").

• Fuel Cells

• Electrolysis

• Flow Through Batteries

• Water Clean-up Electrochemistry

| Gas Diffusion Layer Properties | |

| Material Type | Woven Carbon Fiber |

| Thickness | 0.454 mm (454 microns) |

| Basic Weight (g/m²) | 170 |

| Bulk Density | 0.377 g/cc |

| Air Permeability (s) | 0.104 L/(m²*sec*Pa) |

| Porosity (%) | 63% |

| Carbon Content (%) | 99.5% in woven, variable in coating for hydrophobicity |

| Microporous Layer | Yes, on one side |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: