Versogen Mechanically Reinforced AEMs

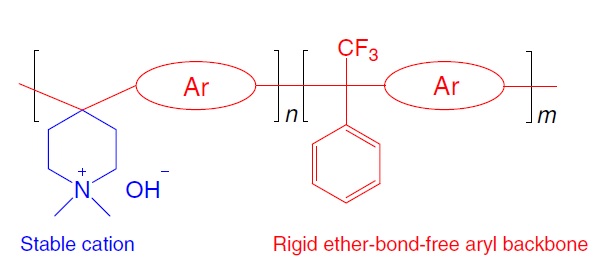

Versogen mechanically reinforced anion exchange membranes (also known as mechanically reinforced PiperION anion exchange membranes) are currently offered in 15 micrometers thickness on Fuel Cell Store. Mechanically reinforced anion exchange membranes (AEMs) are manufactured with functionalized poly(aryl piperidinium) resin material and a microporous ePTFE support. Presence of the microporous ePTFE significantly increases the mechanical robustness of the PiperION membranes. Since part of the membrane is inert and does not have functionalized resin material, the ionic conductivity of the reinforced membranes are usually lower compared to the self-supporting counters with the same thickness. Mechanically reinforced membranes are also known as reinforced composite membranes and ideal for pressurized applications.

The article by Wang et al. entitled "Poly(aryl piperidinium) membranes and ionomers for hydroxide exchange membrane fuel cells" is considered to be an excellent source that describes the polymer chemistry and fuel cell operation of PiperION membranes with hydrogen and CO2-free air reactants at a temperature of 95 °C. This article also investigates the ionic conductivity, chemical stability, mechanical robustness, gas separation, and selective solubility aspects of poly(aryl piperidinium) based AEMs.

The article by Wang et al. entitled "High-Performance Hydroxide Exchange Membrane Fuel Cells THrough Optimization of Relative Humidity, Backpressure, and Catalyst Selection" is considered to be an excellent source that describes the polymer chemistry and fuel cell operation of PiperION membranes under different operational parameters in order to eliminate the anode flooding and cathode drying out issues in order to achieve a blanced water management. With further optimization on the catalyst, a peak power density of 1.89 W/cm2 in H2/O2 and 1.31 W/cm2 in H2/Air have been achieved.

The article by Luo et al. entitled "Structure-Transport Relationships of Poly(aryl piperidinium) Anion-Exchange Membranes: Effect of Anions and Hydration" is considered to be an excellent source that describes the transfer of different anions across AEMs that are manufactured from poly(aryl piperidinium) resin. Nanostructure, hydration or water uptake as a function of the counter anion, phase-separation in regars of its polymer morphology, anion conductivity as a function of water content (vapor or liquid) and anion radius are some of the other aspects that have been discussed in this publication.

The article by Zhao et al. entitled "An Efficient Direct Ammonia Fuel Cell for Affordable Carbon-Neutral Transportation" is considered to be an excellent source that describes economics of hydrogen, methanol, and ammonia as fuel for transportation applications, performance of poly(aryl piperidinium) based AEMs for direct ammonia fuel cell at 80 °C.

The article by Archrai et al. entitled "A Direct Ammonia Fuel Cell with a KOH-Free Anode Feed Generating 180 mW cm-2 at 120 °C" investigates the electrochemical performance of poly(aryl piperidinium) based AEMs for direct ammonia fuel cell at 120 °C.

The article by Endrodi et al. entitled "High carbonate ion conductance of a robust PiperION membrane allows industrial current density and conversion in a zero-gap carbon dioxide electrolyzer cell" investigates the electrochemical performance of poly(aryl piperidinium) based AEMs for electrochemical reduction of CO2 or carbon dioxide electrolyzer applications. This study demonstrated that partial current densities of greater than 1 A/cm2 can be achieved while maintaining high conversion (25-40%), selectivity (up to 90%), and low cell voltage (2.6-3.4 V).

Please note that a current lead time of 2 - 4 weeks is to be expected.