PFSA TE80-R ePTFE Reinforced Proton Exchange Membrane

PFSA TE80-R ePTFE Reinforced Proton Exchange Membrane (PEM) is designed to be used in high differential pressure or high balanced pressure PEM electrolyzers to separate the anode and cathode compartment for generating hydrogen and oxygen gases from water electrolysis reaction. This proton exchange membrane (also known as cation exchange membrane) has a thickness of 80 microns (+/- 5 microns for the thickness variation) and ideally suited for any PEM electrolyzer stacks that demand very high current densities (up to 4 A/cm2) and long operational lifetimes. The mechanical reinforcement in this membrane is based on the microporous ePTFE which has 3-D porous regions where the ionically conducting PFSA is wet impregnated via solution cast method. This material has a backing plastic on one side.

The major benefit of mechanically reinforced PFSA membranes would be their significantly enhanced operational lifetime compared to the unreinforced PFSA membranes due to swelling related stresses being taken up by the ePTFE reinforcement. While one of the major limitations of the mechanically reinforced PFSA membranes is their lower proton or ionic conductivity because of using higher EW resin material (such as 1000 or 1100), PFSA TE80-R ePTFE Reinforced Proton Exchange Membrane is utilizing a much lower EW PFSA resin (~800) and hence have excellent proton conductivity. PFSA resins with lower EW values usually have higher ion exchange capacity (IEC) and higher available acid capacity (AAC) per unit weight of the resin material compared to other PFSA resins and hence the reason why PFSA TE80-R ePTFE Reinforced Proton Exchange Membrane has unparalleled ionic conductivity despite being a relatively thicker membrane.

While this membrane was originally developed to be used in high pressure PEM electrolyzers, the following applications will also benefit greatly from the usage of this membrane: unpressurized or pressurized PEM fuel cells (H2/Air), unpressurized or pressurized PEM fuel cells (H2/O2), direct methanol fuel cells (DMFCs), direct formic acid fuel cells (DFAFC), microbial fuel cells (MFC), electrochemical sensors, vanadium redox flow batteries, and other similar applications. It is always advised that the end-user to take into consideration of the thickness of the PFSA membranes they are intending to use for their particular application and how it may effect the performance positively or negatively.

PFSA TE80-R ePTFE Reinforced Proton Exchange Membrane is based on the chemically stabilized perfluorosulfonic acid material and it is shipped in the acid (H+) form (which is also known as protonic form). Chemical stabilization is also known as end-group stabilization where the carbon atoms that end of the PFSA polymer chains are fully fluorinated. Chemically stabilized PFSA membranes will exhibit substantially lower fluoride ion release compared to the PFSA membranes manufactured from unstabilized PFSA resin. Functional groups (also known as sulfonic acid sites) for this PFSA membrane are based on the long side chain for its chemical structure.

Proton exchange membranes are also known as cation exchange membranes in the market. This PFSA membrane performs as a separator and solid electrolyte (without the need of a liquid acid) in a variety of electrochemical cells that require the membrane to selectively transport protons or other various cations across the cell junction (or between anode and cathode catalyst layers). The polymer is chemically resistant and durable.

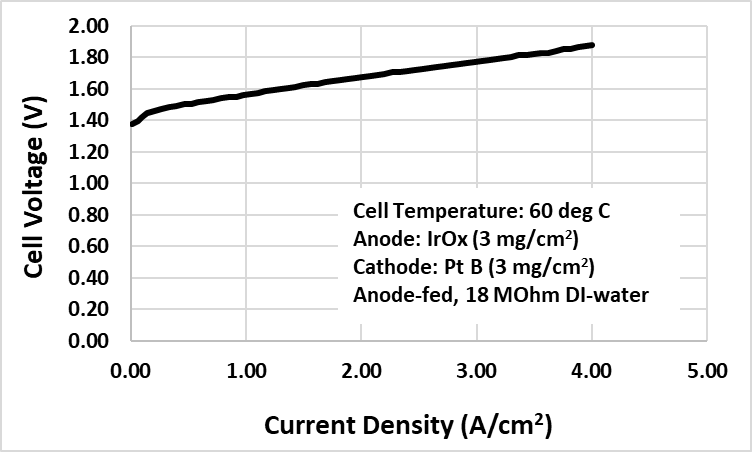

Electrochemical performance:

The polarization curve for this membrane was taken with a specialty electrochemical cell and it is provided solely for examplary purposes. It likely that customers purchasing this membrane product may or may not be able to replicate this data as a result of the electrochemical performance being dependent not only on the CCM configuration, but also the other components such as anode and cathode diffusion layers, quality of the DI-water used, temperature and pressure value for the cell, testign hardware design and components used in the testing hardware itself, etc.

Please contact us at sales@fuelcellstore.com for the SDS and technical data sheets (TDS).

| Membrane Properties | |

| Thickness | 80 micrometers (+/- 5 micrometers) |

| Conductivity (S/cm) | > 0.060 S/cm |

| Tensile Strength - max. (MPa) | > 35 / 35 MPa (MD/TD) |

| Elongation to Break (%) | > 100% / 100% (MD/TD) |

| Membrane Hydrolytic Properties | |

| Water content (% water) | >20% |

| Linear Expansion | <5% for MD and <5% for TD |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: