Aquivion® D83-24B

Aquivion® D83-24B is a perfluorosulfonic acid (PFSA) ionomer dispersion that exhibits an Equivalent Weight (EW) of 830 g/eq. Polymer concentration is 24%. Solvent system is >99% water and is free of ethers. This dispersion is based on the standard composition, which is not chemically stabilized. The products that are manufactured with Aquivion® D83-24B dispersion would have slightly lower lifetime compared to products that are containing chemically stabilized dispeersions such as Aquivion® D98-25BS. Chemical stabilization process is also known as end group conversion in which a large amount of polymer end groups are converted to their inert "CF3" configuration, and as such provides excellent lifetime.

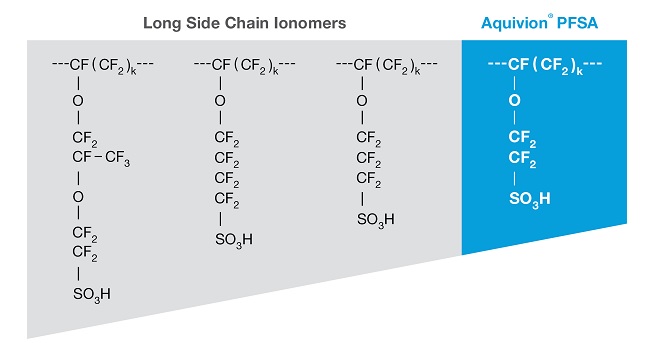

Aquivion® PFSA dispersions are based on the unique Short Side Chain (SSC) copolymer of Tetrafluoroethylene (TFE) and Sulfonyl Fluoride Vinyl Ether (SFVE) F2C=CF-O-CF2CF2-SO2F produced by Solvay. The unique SSC copolymer allows higher crystallinity, improved mechanical properties, and better proton conductivity compared to Long Side Chain forms of the PFSA dispersions. Solvay Aquivion® PFSA ionomers are currently being offered in chemically stabilized and standard forms. Any product that is manufactured with chemically stabilized dispersion (such as self-supporting membranes, mechanically reinforced membranes, MEAs, CCMs, catalyzed electrodes, etc.) will exhibit substantially lower fluoride ion release compared to the standard ionomer (also called non-stabilized ionomer) – a sign of improved chemical durability.

The PFSA dispersions (also called ionomer) are supplied in the acidic form (-SO3H) and are available in various solvent systems, EWs and concentrations. This particular dispersion is water based for its solvent system or dispersion medium.

These dispersions can be used to produce PEM fuel cell electrodes and electrochemical cell electrodes, to manufacture or repair ion exchange membranes, to produce super-acid catalysts, and for the surface treatment of PTFE membranes to improve wetting behavior.

• Very high concentration of functional groups for strong proton (or Na+, K+, Li+, etc.) conductivity

• High softening point for high temperature operation well above 80 ºC

• Strong water retention for better fuel cell operation at low-humidity conditions for membranes or catalyst inks that are utilizing this dispersion material

Aquivion® PFSA dispersions are based on the short side chain morphology and they would enable the manufacturing of products (membranes, dispersions, etc.) that have either better mechanical properties at the same IEC (ion-exchange capacity) or a higher IEC at the same mechanical properties than the products that are using long side chain (LSC) based PFSA dispersions. A comparison of Short Side Chain and Long Side Chain PFSA dispersions from a chemical composition perspective is provided in the following image.

Solvay Aquivion dispersions are considered hazardous items under DOT and IATA regulation. 125 mL and 250 mL dipsersions will incur a hazardous fee to accommodate the regulations based on the final shipping location.

Please note that Solvay Aquivion dispersions contain solvents that may compromise the seals of the bottles if the solvents are left in direct contact with the lids for long periods of time. We recommend always storing the bottles in an upright orientation as soon as the shipment is received to lessen the likelihood of inadvertent leakage.

Aquivion® D83-24B Technical Data Sheet

Aquivion® D83-24B Technical Data Sheet

Properties that are provided on the FuelCellStore website are directly taken from the technical documentation sheets provided by the manufacturer for consideration as "typical properties" and not to be construed as specifications.

A typical lead time of 3-4 weeks is to be expected.

| Solvay Aquivion Dispersions | |

| Appearance | Off-white |

| Form | Liquid |

| Density | 1.15 g/cm3 (at 20 deg Celsius, ASTM D1475) |

| Equivalent Weight (EW) | 810 to 850 g/eq (Internal Method) |

| Polymer Concentration | 24 wt% |

| Solvent System | >99% water, free of ethers % |

| Total Acid Capacity | 1.17 to 1.23 meq/g (Internal Method) |

| Viscosity | 5 to 15 mPa.s (ASTM D2196) |

| HSE/Transport Classification | Corrosive |

| Flammability at ambient conditions | Non flammable |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: