Celtec High Temperature PEM Fuel Cell Anode Electrode

Celtec High Temperature PEM Fuel Cell Anode Electrode:

Celtec High Temperature PEM Fuel Cell Anode Electrode:BASF offers the state-of-the art anode electrode for high-temperature proton exchange membrane (HT-PEM) fuel cells and other relevant applications. This product is also known as Celteh P1100W Anode in the fuel cell industry and utilizes a woven carbon cloth with microporous layer as its gas diffusion layer. It is capable of operating in the temperature range of 120 and 180 °C and can tolerate large concentrations of carbon monoxide and reformate fuel streams used for such applications. This high performance anode electrode technology enables high temperature PEM fuel cell systems, PBI membrane based PEM fuel cell systems, PBI-copolymer membrane based fuel cell systems, and other high temperature PEM utilizing fuel cells to demonstrate exceptional performance with various fuels (pure H2, reformate, etc.) and long operational lifetimes.

This Celtec P1100W anode electrode has dimensions of 23.2 cm X 27.8 cm and sold as individually packaged electrode sheets. The anode catalyst is based on BASF's proprietary platinum alloy composition (also known as Pt-alloy) with a specialty carbon support and the platinum metal loading for this anode electrode is approximately ~1 mg/cm2.

For any other tailored or customized high temperature proton exchange membrane fuel cell (HT-PEMFC) anode electrodes, please contact us at sales@fuelcellstore.com.

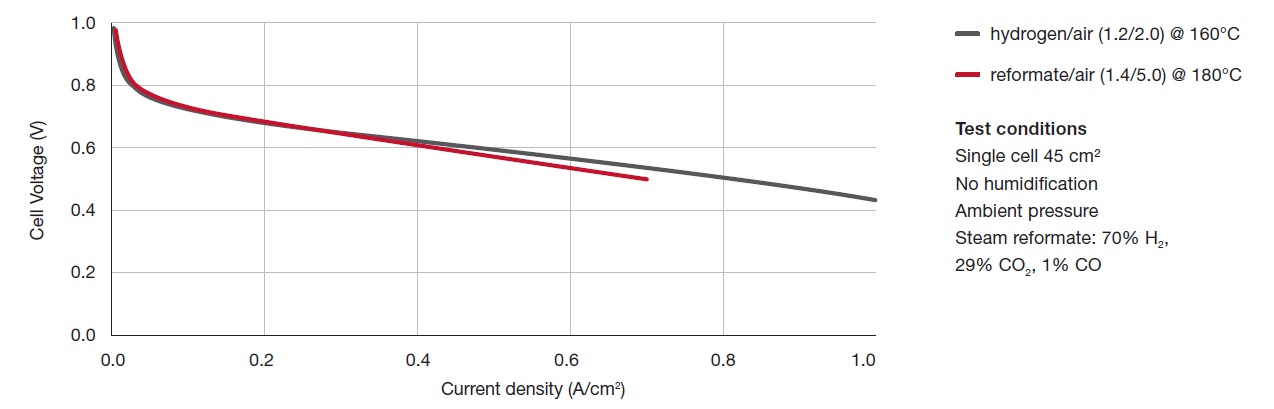

Hydrogen/Air and Reformate/Air reactant based fuel cell performance of Celtec®-P MEAs are provided below.

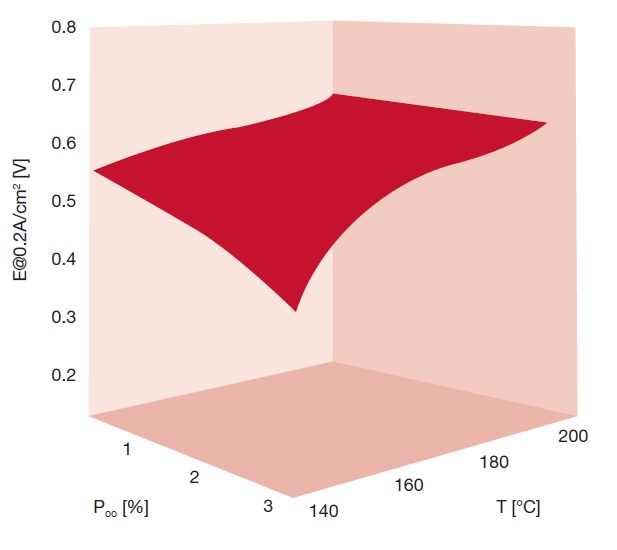

One of the major benefit of the high temperature proton exchange membrane fuel cell technology is the capability of consuming the reformed hydrogen stream, it is essential that MEAs used in such electrochemical devices have excellent carbon monoxide tolerance. During the reformation reaction, there is a small amount of the carbon monoxide gas generated in the fuel stream exiting the reforming catalyst bed, and presence of carbon monoxide can impact the overall fuel cell performance. BASF Celtec®-P MEAs uses a proprietary anode and cathode catalysts in order to allow the Celtec®-P MEAs tolerate high levels of carbon monoxide compared to the other commercial high temperature PEMFC MEAs. The following graph provides an example performance curve for Celtec®-P MEAs at different CO concentrations as a function of temperature.

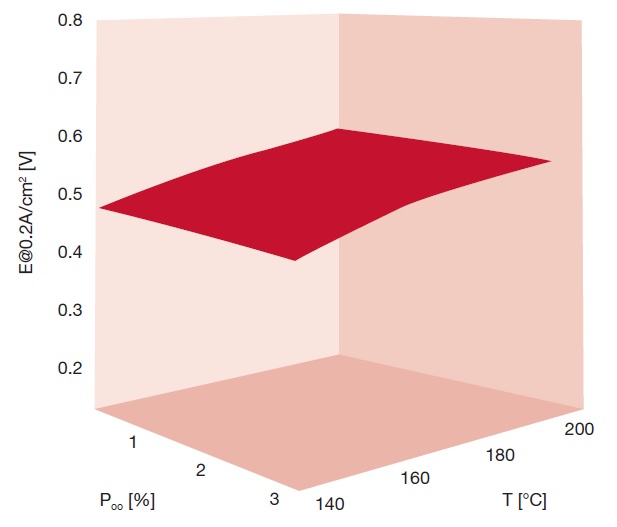

Conventional high temperature PEMFC devices would usually use a polybenzimidazole PBI) or a co-polymer of PBI membrane that is phosphoric acid doped after the production of the membrane. Such membrane activation and containment of the liquid acid inside the membrane result in acid leaching phenomenon. PEM fuel cells generate water as the main by-product at the cathode side and presence of water further impacts the acid leaching phenomenon with the conventional PBI membrane. Celtec®-P MEAs utilized an advance form of PBI membrane where the proprietary tetraamino monomer and dicarboxylic acid monomer are first reacted via polycondensation reaction in phosphoric acid and then a solution casting & hydrolysis step is carried out in order to obtain the Celtec®-P membrane. This sol-gel synthesis protocol allows the PBI membrane to attain a novel morphology where the phosphoric acid is contained inside the membrane more effectively and has less acid leaching issues compared to conventional PBI membranes. Laboratory test results showed that operational lifetimes of exceeding 20,000 hours can easily be achieved with Celtec®-P MEAs and Celtec®-P membranes. The following graph provides the robust performance of Celtec®-P MEA against different humidity conditions.

For customers that purchased this product, a copy BASF Fuel Cell Handbook will be provided separately (free-of-charge) in an electronic format such as PDF file.

An article by Michael G. Waller et al. entitled "Performance of high temperature PEM fuel cell materials. Part 1: Effects of temperature, pressure and anode dilution" demonstrates the use of Celtec electrodes within a high temperature PEMFC environment within a temperature range of 160-200 deg Celsius, 101-200 kPa, and H2 concentrations of 30% to 100%.

An article by Thomas J. Schmidt entitled "Durability and Degradation in High-Temperature Polymer Electrolyte Fuel Cells" demonstrates the use of Celtec MEA with Celtech electrodes for 18000 hours of operation within a high temperature PEMFC environment and very low voltage degradation rates.

An article by Thomas J. Schmidt entitled "High-Temperature Polymer Electrolyte Fuel Cells: Durability Insights" investigates degradation mechanisms during start/stop operation and presents a better understanding of corrosion effects in high-temperature MEAs by using Celtec MEAs with Celtec electrodes.

An article by David Aili et al. entitled "Polybenzimidazole-Based High-Temperature Polymer Electrolyte Membrane Fuel Cells: New Insights and Recent Progress" discusses the current status of the high temperature PEM fuel cell research, summarizes the electrochemical performance of Celtec MEA with Celtec electrodes and other supplier's products.

An article by D. C. Seel et al. entitled "High-temperature polybenzimidazol-based membranes" discusses PBI synthesis methods, membrane casting and doping steps, mechanical strength and stability of polybenzimidazoles, other self-supporting and composite membranes relevant to high temperature PEMFC applications, conductivity of these membranes, catalysts, electrodes, and membrane electrode assemblies including Celtec MEAs with Celtec electrodes, and finally summrizes the durability and electrochemical performance of the commercial MEAs/electrodes from various suppliers.

An article by F. J. Pinar et al. entitled "Effect of Compression Cycling on Polybenzimidazole-based High-Temperature Polymer Electrolyte Membrane Fuel Cells" discusses the compression cycling of Celtec MEAs with Celtec electrodes.

An article by Vladimir Gurau and Emory S. De Castro entitled "High Speed, Low Cost Fabrication of Gas Diffusion Electrodes for Membrane Electrode Assemblies" discusses the automated high speed and low cost production for Celtec electrodes and shares insight to how the production method can effect the final electrochemical performance of the electrodes.

An article by Vladimir Gurau and Emory S. De Castro entitled "Prediction of Performance Variation Caused by Manufacturing Tolerances and Defects in Gas Diffusion Electrodes of Phosphoric Acid (PA)–Doped Polybenzimidazole (PBI)-Based High-Temperature Proton Exchange Membrane Fuel Cells" discusses the prediction of performance variation caused by the automated production for Celtec MEAs with Celtec electrodes.

A research project conducted by Fluid Cell company entitled "State-of-the-art of PEM FCs for stationary applications" presents the electrochemical performance of Celtec MEAs with Celtec electrodes for stationary applications.

An article by Arvind Kannan et al. entitled "Long term testing of start–stop cycles on high temperature PEM fuel cell stack" discusses long term performance testing with frequent start-stop cycles and also under uninterrupted operation for the Celtec MEA with Celtec electrodes.

An article by Thomas J.Schmidt and Jochen Baurmeister entitled "Properties of high-temperature PEFC Celtec®-P 1000 MEAs in start/stop operation mode" investigates the electrochemical performance of Celtec MEA with Celtec electrodes for 6000 hours with start/stop cycles.

A typical lead time of 1-2 weeks is to be expected.

| Catalyst Properties | |

| Catalyst Type | Platinum alloy supported on specialty carbon support |

| Loading | ~1.0 mg/cm2 for platinum metal |

| Gas Diffusion Layer Properties | |

| Material Type | Woven Carbon Fiber Cloth |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: