Rayon Graphite Felt - 6.3 mm thick

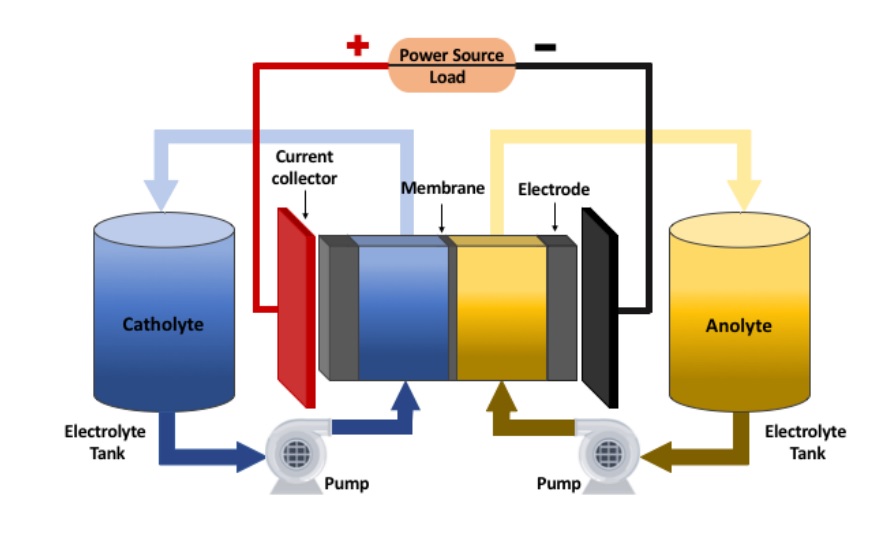

Rayon graphite felt product is manufactured from viscose precursor (which is a semi-synthetic fiber made from natural sources of regenerated natural cellulose) and it is pre-fired at 4532 ºF (2500 ºC) in order to complete the graphitization of the starting precursor material. This is a soft felt material with good flexibility and compressibility. It is easy to cut to different sizes using different cutting tools such a die cutter, a pair of scissor, or a heavy duty office paper trimmer. Rayon based graphite felt materials are usually used for redox flow batteries and microbial fuel cells as the electrode or current collector, insulating layer for furnaces, or as heat shields and heat sinks and various other relevant applications. Rayon felt products have higher carbon and lower ash content in comparison to PAN felt counterparts. Electrical and thermal conductivity of Rayon Graphite felt products are higher than that of Rayon Carbon Felt products. Following redox flow battery image is courtesy of Alejandro Clemente et al. and furnace thermal insulation is courtesy of Vac Aero International to show exemplary applications that can use felt products.

This product has a thickness tolerance of 6.3 mm +/- 1 mm and interested parties should procure a small sample first for their intended application prior to placing an order for bulk volume.

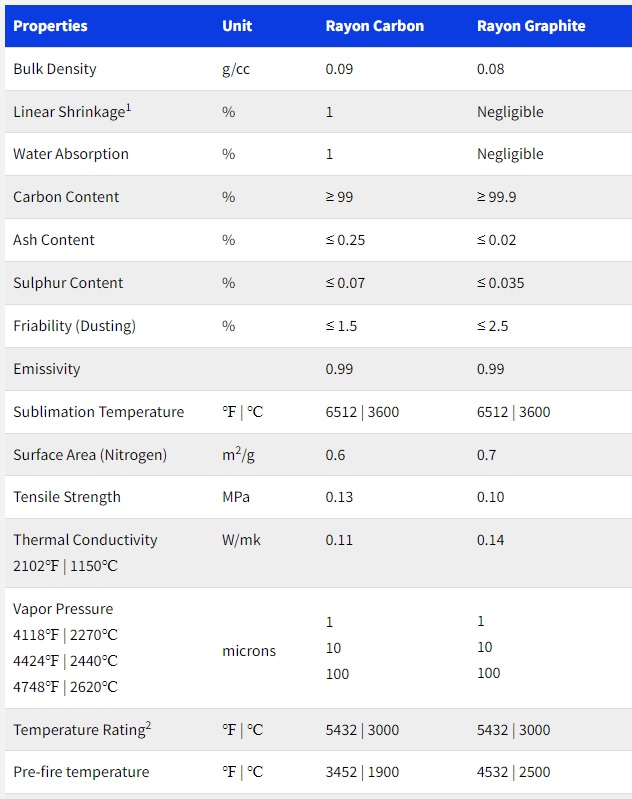

Comparison of Rayon graphite and Rayon carbon felts products are given in the table below.

- Redox flow batteries

- Microbial fuel cells or biofuel cells

- Furnace insulation & parts

- Heat shields & sinks

- Backing strips for soldering & welding

- Cathode in flow battery applications

- Reaction surface for other electrochemical processes or used as a catalyst substrate

- Glass blower, plumber pads & wicks in ultralight stoves

- Thermal insulators and automotive exhaust linings

A typical lead time of 3-4 weeks to be expected for this product.

| Gas Diffusion Layer Properties | |

| Thickness | ~ 6.3 mm (~6300 microns) |

| Bulk Density | 0.08 g/cm3 |

| Tensile Strength | 0.10 MPa |

| Carbon Content (%) | ≥99.9% |

| Ash Content | ≤ 0.02% |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: