HYDRO-LAT 1400 AND HYDRO-LAT 2400 GAS DIFFUSION LAYERS WITH HYDROPHILIC MICROPOROUS LAYER

Background

Electrochemical technologies have been widely adopted for various commercial applications such as fuel cells, electrolyzers, electrochemical CO2 reduction, and numerous other applications because of their inherent high efficiencies. One of the critical components of such technologies has been the gas diffusion layer (GDL) that is sandwiched between the flow field and the membrane. The main functions of the GDL in an electrochemical cell are:

- enabling the transfer of reactants to the catalyst site or catalyst layer,

- establishing electrical contact between the catalyst layer on the membrane and flow field,

- spreading out the reactants evenly inside the cell,

- removing the by-product water generated inside the cell, and

- lowering the catalyst loading (in the case of GDL with microporous layer) to lower the cost of the final membrane electrode assembly.

Currently Available Commercial Gas Diffusion Layer Products

Commercial carbon-based gas diffusion layers are mainly used for PEM fuel cells and PEM electrolyzers, as these are the two most dominant technologies on the market at the moment. Standard carbon-based gas diffusion layers can be categorized into four main sections, namely:

- carbon paper substrate (no MPL and no PTFE),

- carbon cloth substrate (no MPL and no PTFE),

- carbon paper with MPL,

- and carbon cloth with MPL.

Gas diffusion layer is a very generic term and any material that is being used as a diffusion layer can technically be called a gas diffusion layer, regardless of whether or not the GDL has a Microporous Layer (MPL) or a PTFE coating. In short, any carbon-based product that falls under these four categories can be called a gas diffusion layer.

Originally, GDLs did not include any MPL or PTFE treatment that would help mitigate flooding issues within a fuel cell from by-product water. In order to prevent catalyst flooding issues, commercial GDLs with MPL typically use PTFE as a binder to create a semi-porous carbon layer. Presence of PTFE provides hydrophobicity for the final product. Hydrophobicity reduces the surface contact, allowing water to more easily be removed from the catalyst layer. For PEM electrolyzer applications, base forms of GDLs (without MPL) or standard GDLs with low levels of PTFE in the MPL are most often utilized. While GDLs with PTFE binders in the MPL have advanced fuel cell technologies greatly, emerging electrochemical technologies have indicated other forms of GDLs are needed as well.

Emerging Needs for GDLs with Hydrophilic MPLs

There are several niche electrochemical applications that require the electrolyte to fully wet the surface of the electrodes. Some of those applications include:

- High surface area GDLs for supercapacitors with organic electrolytes

- Niche battery chemistries with organic electrolytes

- Vapor-fed PEM electrolyzers,

- Cathode-fed PEM electrolyzers,

- Passive PEM fuel cells,

- Lithium-sulfur batteries

Current literature also shows researchers pursuing aqueous electrolytes for some of these niche electrochemical applications. While conventional carbon paper and carbon cloth base-substrates would enable wetting by the organic electrolytes, they are not suitable for such niche applications due to their low surface area. On the other hand, typical GDLs with MPL would provide the high surface area aspect needed, the presence of super-hydrophobic PTFE would prevent the electrode surface from wetting. Hence, the lack of commercially available GDLs with hydrophilic MPL has hampered the development of these high efficiency electrochemical technologies. There is a need for high surface area GDLs with hydrophilic MPL products that can be wetted by either organic or aqueous electrolytes in order to further the development of these emerging electrochemical devices and technologies.

Hydro-LAT 1400 and Hydro-LAT 2400 GDLs with Hydrophilic MPL

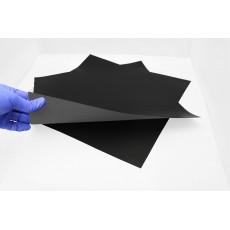

Hydro-LAT 1400 and Hydro-LAT 2400 are new product offerings by Fuel Cell Store. FuelCellsETC (the manufacturer of ELAT) manufactures this innovative new GDL with a hydrophilic MPL. The base material consists of a carbon cloth substrate with a thickness of ~410 microns. The MPL is made up of high surface area carbon black nanopowder and a proprietary binder where a hydrophilic and a cation conductive polymer solution has been used. In order to establish the hydrophilic MPL, high surface area carbon is first mixed with various solvents and mixed with the hydrophilic binder, and finally deposited over the carbon cloth substrate. The hydrophilic binder used for Hydro-LAT has excellent chemical, physical and thermal properties. This makes Hydro-LAT ideal for very harsh or demanding applications. Since there is no PTFE in the MPL, Hydro-LAT has excellent wettability characteristics. The estimated water contact angle for this hydrophilic MPL is <60 degrees.

Hydro-LAT 1400 has hydrophilic MPL only on one side of the GDL and has a thickness of 410-450 microns. While Hydro-LAT 2400 has hydrophilic MPL on both sides of the GDL with a thickness of 450-500 microns.

If desired, either Hydro-LAT product can be coated with desired catalyst materials on one or both sides, such as Pt/C, Pt Black or 100+ other electrochemical application-relevant catalytic materials depending on the end use.

Enter the code in the box below: