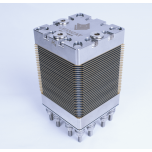

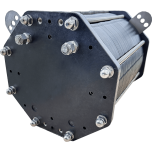

Titan EZ-180 Stack

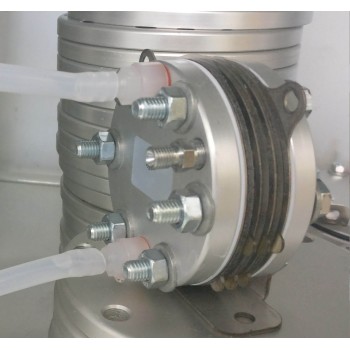

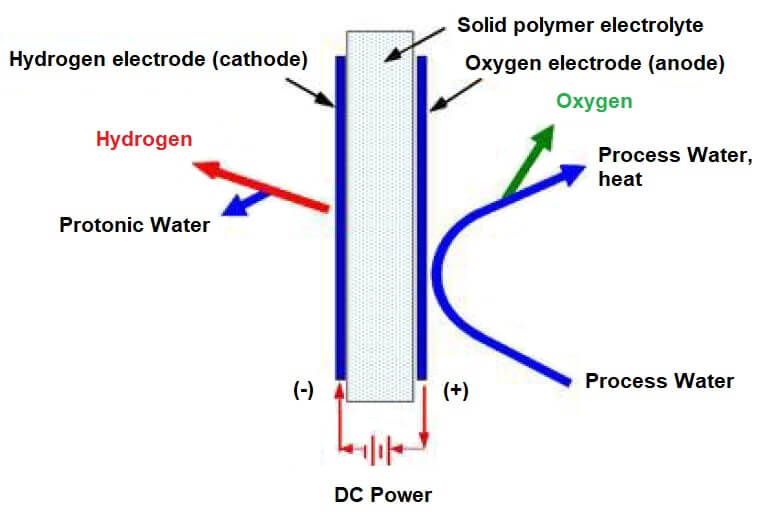

Titan series PEM Electrolyzer Stacks is an advanced patented product, which is lower voltage and higher efficiency, energy-saving and of environmental protection, producing hydrogen and oxygen through the electrolysis of pure water (without adding alkali).

The proton exchange membrane (PEM), which only allows water and positive ions to cross between compartments. The membrane also serves as the electrolyte in the cell, eliminating the need for hazardous liquid electrolytes such as concentrated potassium hydroxide. PEM water electrolysis simply splits pure deionized water (H2O) into its constituent parts, hydrogen (H2) and oxygen (O2), on either side of this membrane. When a DC voltage is applied to the electrolyzer, water fed to the anode, or oxygen electrode, are oxidized to oxygen and protons, while electrons are released. The protons (H+ ions) pass through the PEM to the cathode, or hydrogen electrode, where they meet electrons from the other side of the circuit, and are reduced to hydrogen gas. The two reactions that occur in the cell are as follows:

1. 2H2O -> 4H+ + 4e- +O2

2. 4H+ + 4e- -> 2H2

Thus, the only possible components of the streams are hydrogen, oxygen and water moisture, as shown in Figure 1 below.

• Redundant renewable energy transformation and storage

• Lab experiment and teaching

• Laboratory analytic instrument

• Hydrogen healthy care industrial

• Hydrogen beauty industrial

• Fuel for special field

• Hydrogen supply for fuel cell

• Other pure H2 application field

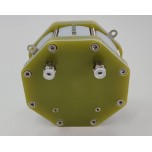

• Produce hydrogen by electrolysis pure water (forbid adding alkaline)

• No corrosion or pollution

• High hydrogen purity

• Low electrolyzer cell resistance

• No heat and long desiccant replacement cycle

• Lower power consumption and high electrolysis efficiency

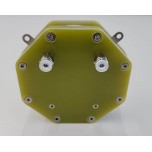

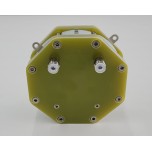

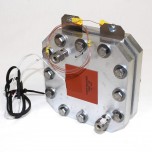

| Model | Unit | Titan EZ-60 | Titan EZ-120 | Titan EZ-180 | Titan EZ-240 | Titan EZ-300 | Titan EZ-500 | Titan EZ-800 | Titan EZ-1000 | Titan EZ-1300 | Titan EZ-1500 | Titan EZ-2000 |

| Cells | - | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | 5 | 6 | 4 |

| Stack Diameter | mm | 85 | 85 | 85 | 85 | 138 | 138 | 138 | 138 | 138 | 138 | 140 |

| Active Area Diameter | mm | 40 | 40 | 40 | 40 | 80 | 80 | 80 | 80 | 80 | 80 | 94 |

| H2 Flow Rate | mL / min | 0 - 60 | 0 - 120 | 0 - 180 | 0 - 240 | 0 - 300 | 0 - 500 | 0 - 800 | 0 - 1000 | 0 - 1300 | 0 - 1500 | 0 - 2000 |

| O2 Flow Rate | mL /min | 0 - 30 | 0 - 60 | 0 - 90 | 0 - 120 | 0 - 150 | 0 - 250 | 0 - 400 | 0 - 500 | 0 - 650 | 0 - 750 | 0 - 1000 |

| Voltage | V (DC) | 2 | 4 | 6 | 8 | 2 | 4 | 6 | 8 | 10 | 12 | 8 |

| Max Input Current | A (DC) | 9 | 9 | 9 | 9 | 40 | 40 | 40 | 40 | 40 | 40 | 72 |

| Water Consumption Rate | cc / hr | 4 | 8 | 12 | 16 | 18 | 30 | 48 | 60 | 78 | 90 | 120 |

| Operating Temperature | - | 40°F to 113°F (5°C to 45°C) | ||||||||||

| Output Pressure | - | 0 - 10 barg (0 - 145 psi) | ||||||||||

| Membrane Type | - | Nafion PFSA | ||||||||||

| Sintered Titanium diffusion medium | ||||||||||||

| Precious metal electrode | ||||||||||||

| Need deionized or re-distilled water | ||||||||||||

| Water Resistivity: >1 MΩ*cm | ||||||||||||

| Water Conductivity: <1 us/cm | ||||||||||||

| Estimated Lifetime: If the water quality and power supply are always in ideal condition you can expect about 10,000 hours of operation. | ||||||||||||

General lead time of two weeks to be expected.

Titan EZ-180 Stack is formerly known as QLC-180 PEM Electrolyzer Stack.

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below:

Titan EZ-180 Stack Manual

Titan EZ-180 Stack Manual