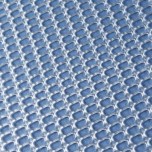

Platinized Titanium Fiber Felt

Platinized titanium felts are primarily used in electrolyzer single cells and stacks as the flow field or diffuser material, particularly on the oxygen (anode) side. Since electrolyzer hardwares cannot use carbon-based gas diffusion layers (GDLs) at the oxygen evolution electrode due to immediate oxidation of carbon to CO2 (if the medium is acidic) or carbonate ions (if the medium is basic) during the electrolysis reaction, platinized titanium felt becomes an ideal candidate as the diffusion medium and also provide electrical contact between the anode catalyst layer and bipolar plate or current collector component at the anode side. Our platinized titanium felts are produced from titanium fibers that has been compressed to flattened form and annealed, ensuring a smooth, flat surface suitable for use in electrolyzer and have gone through our proprietary platinization process to extend the lifetime of titanium fiber felt greatly.

Platinized titanium felts are primarily used in electrolyzer single cells and stacks as the flow field or diffuser material, particularly on the oxygen (anode) side. Since electrolyzer hardwares cannot use carbon-based gas diffusion layers (GDLs) at the oxygen evolution electrode due to immediate oxidation of carbon to CO2 (if the medium is acidic) or carbonate ions (if the medium is basic) during the electrolysis reaction, platinized titanium felt becomes an ideal candidate as the diffusion medium and also provide electrical contact between the anode catalyst layer and bipolar plate or current collector component at the anode side. Our platinized titanium felts are produced from titanium fibers that has been compressed to flattened form and annealed, ensuring a smooth, flat surface suitable for use in electrolyzer and have gone through our proprietary platinization process to extend the lifetime of titanium fiber felt greatly.

While the most industrial applications operate their electrolyzers in the anode-fed mode and this product makes an excellent diffusion medium for the oxygen evolution electrode, it can also be used as an ideal diffusion medium for researchers conducting cathode-fed electrolyzer research.

For unitized fuel cells or electrolyzers or regenerative electrochemical devices systems, platinized titanium felt can be used at anode or cathode as the diffusion medium. Electrochemical oxygen concentrators, electrochemical inerters, certain class of batteries such as redox flow batteries, etc. can also benefit from this product as the diffusion medium regardless of the nature of the reactants.

When Should I use a Platinized Titanium Fiber Felt?

Untreated titanium felt will not be consumed as a carbon gas diffusion layer (GDL) will (in an electrolysis setup), however, the presence of the oxygen does have an impact if the electrolyzer is being operated at slightly higher pressures than ambient pressure (1 bar to 3 bars). Untreated titanium surface will quickly form an electrically insulation oxide layer (TiO2) under high O2 pressures that will eventually affect the efficiency of the overall system. This oxide coating will behave as an electrical insulator and will therefore increase the interfacial resistance in the cell, thereby lowering the electrochemical performance.

The oxidation of titanium can be prevented by gold coating or platinum coating. The surface platinization of titanium generates a coating that is electrically conductive and chemically stable under regular electrolysis operational conditions and extends the lifetime of the bulk of titanium, which is ideal for applications that demand high performance and long lifetime. Prevention of the formation of TiO2 would greatly stabilize the electrochemical performance of the electrolyzer or the intended electrochemical device.

Function of the Platinum Coating for This Product

The main functionality of the platinum coating is to maintain the electrical conductivity of the substrate itself for demanding applications such as longer operational lifetime or pressurized electrolyzer (up to 100 psi) applications. In the industry, it has been observed that platinized titanium fiber felt products can be used at the anode side of the PEM electrolyzer hardware at such pressure values. Higher pressures than 100 psi would create safety issues for titanium fiber felt substrate in presence of pure oxygen even if the environment is fully wetted. Platinum coating does not have a continuous layer for its structure. The estimated platinum metal loading for this product is approximately 60-80 micrograms per cm2 of the substrate's physical dimensions.

Catalytic Activity of the Platinum Coating for this Product

The platinum coating in this product does not have any catalytic activity. Catalysis requires the material of interest to have sufficient surface defects and also sufficient loading for the catalytically active component. Platinum particles in the coating does not have the essential surface defects and has zero catalytic activity for most chemical or electrochemical reactions and hence, this product should not be used for catalysis reactions or applications that require catalytically active materials.

• Porosity: approximately 53-56%

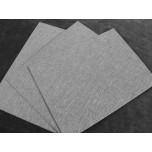

• Thickness: 0.2-0.3 mm (uncompressed height)

• Dimensions: Various sizes available.

This product is usually available as in-stock item, otherwise the lead times would be around 2 weeks.

| Gas Diffusion Layer Properties | |

| Porosity | approximately 53-56% |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: