Fumasep FAB-PK-130

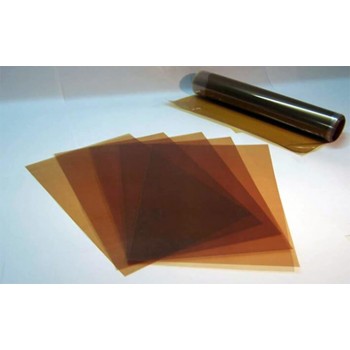

Fumasep FAB-PK-130 is a PK reinforced Anion Exchange Membrane (AEM) with high proton blocking capability, high selectivity, very high mechanical stability, and high stability in acidic and caustic environment. The polymer backbone for this membrane is based on a proprietary hydrocarbon resin.

Fumasep FAB-PK-130 is designed for the processing of concentrating acidic solutions, electrodialysis and electrodialysis with bipolar membranes.

Fumasep FAB membrane comes in either a 10cm x 10cm or 20cm x 30cm size sheet.

Fumatech membranes are highly sensitive to differences in humidity and moisture content. Therefore the membranes can vary +/- 0.5cm from the original cut sizes. Also due to this sensitivity the manufacturer expects wrinkles to form, however soaking the membranes in deionized water will return the membranes to the full size planar state according to the manufacturer.

• Applications: Process for concentrating acidic solutions, electrodialysis and electrodialysis with bipolar membranes. This membrane can also be used for standard alkaline fuel cell and electrolysis applications that utilizes slightly alkaline solutions (1-2 Molar). Another application that can benefit greatly from this membrane is non-aqueous redox flow batteries that utilize organic solvents such as acetonitrile, etc. The dimension change or swelling of the membrane for non-aqueous redox flow battery applications would predominantly depend on the chemical composition of the electrolyte used. Mechanically reinforced fluorinated anion exchange membranes would demonstrate increased mechanical stability and lower solvent mediated crossover compared to non-reinforced counterparts for non-aqueous redox flow battery applications.

• Type: Anion Exchange Membrane

• Stability Range (pH) at 25°C: 0 - 14

• Thickness: 130 micrometers (5.1 mil)

• Sizes: 10cm x 10cm, 20cm x 30cm

Fumasep FAB-PK-130 Technical Specification Sheet

Fumasep FAB-PK-130 Technical Specification Sheet

Keep membrane package closed / sealed when unused. Store, handle and process the membrane in a clean and dust-free area. Use only new and sharp knives or blades, when cutting the membrane. Always wear protective gloves when handling the membrane. Handle with care, be sure not to puncture, crease or scratch the membrane, otherwise leaks will occur. All surfaces in contact with the membrane during handling, inspection, storage and mounting must be smooth and free of sharp projections.

Dry Form: The membrane can be stored dry for an unlimited amount of time. However, the membrane has to be conditioned (washed and rinsed) prior to use.

Wet Form: Storage for short and medium time scale (hours up to several weeks) may be done in unsealed containers in 0.5 - 1.5 wt% NaCl solution or comparable neutral pH electrolytes. For storage over a longer time period a sealed container is recommended using afore said electrolyte with ca. 100 ppm biocide (NaN3) to avoid biological fouling.

The membrane is delivered in the bromide form and dry. Depending on application and cell design, assembling is possible in dry form (without pretreatment) or wet form. For optimum performance it is recommended to rinse the membrane in NaCl solution (e.g. 0.5 M NaCl solution at 25°C for 24 hrs) to remove any additive from the membrane. Place the membrane sample between stabilizing meshes / spacers in order to avoid curling. Do not let the membrane dry out since micro-cracks may likely occur during shrinkage.

For standard alkaline fuel cell / electrolysis applications, the membrane should be converted into OH-form by treating it with 0.5 – 1.0 M NaOH or KOH solution: Put the membrane sample in an aqueous solution of 0.5 – 1.0 M NaOH or KOH for at least 24 h at 20°C – 30°C. After rinsing with demineralised water (pH ~ 7) the membrane is ready to use. Use closed container to avoid CO2 contamination (carbonate formation that may affect conductivity). The membrane in OH-form must be stored under wet / humidified and CO2-free conditions, avoid drying out of the membrane in OH-form. Long-term storage in dry conditions should be preferably done in carbonate, Cl- or Br-form.

For electrochemical CO2 reduction applications, the anion exchange membrane should be converted to the carbonate or bicarbonate form by treating the membrane initially with 0.1 to 0.5 M KOH or NaOH solution and then with 0.1 to 0.5 M water soluble carbonate or bicarbonate salt solutions (such as potassium carbonate or potassium bicarbonate that is dissolved in de-ionized water or distilled water). Fully submerging the anion exchange membrane into KOH or NaOH solution for 6 to 12 hours and then to the desired carbonate or bicarbonate salt solution for a period of 48-72 hours would be sufficient to fully convert the membrane into either carbonate or bicarbonate form. After rinsing the membrane (which is in the carbonate form) with deionized water or distilled water, it can be assembled inside the electrochemical setup for electrochemical CO2 reduction experiments. While the submersion of the membrane into the KOH or NaOH can be skipped, for such situations, a longer submersion time may be required in order to fully convert the membrane to carbonate or bicarbonate form. Initial conversion to OH- form significantly improves the carbonate ion exchange process due to expanded pore sizes.

For other electrochemical (electrodialysis, desalination, electro-electrodialysis, reverse electrodialysis, acid recovery, salt splitting, etc.) and non-electrochemical applications, the membrane should be converted into the anionic form that is relevant for the intended application. For example, if the application is requiring the Cl- anions to be transferred through the membrane, then this anion exchange membrane needs to be converted into the Cl- form. In order to convert this membrane into Cl- form, it needs to be submerged into a 1-2 M salt solution of NaCl or KCl (dissolved in deionized water) for a period of 24-72 hours and then rinsed with deionized water to remove the excess salt from the membrane surface. Or if the intended application is requiring to transfer sulfate anions, then this anion exchange membrane needs to be converted into the sulfate form prior to its assembly into the cell. A neutral salt solution of Na2SO4 or K2SO4 would usually be sufficient to achieve the full conversion of membrane into the sulfate form after fully submerging the membrane into the salt solution for 24-72 hours at room temperature.

If you have any concerns about storage, chemical stability and pretreatment before proceeding, please feel free to contact us for further information.

Please note that a current lead time of one to two weeks is to be expected.

| Membrane Properties | |

| Membrane | Anion Exchange Membrane |

| Thickness | 110 - 140 µm (microns) |

| Appearance / Color | Brown |

| Backing Foil | None |

| Delivery Form | Dry |

| Reinforcement | PK |

| Counter Ion | Bromide (Br-) |

| Density | 10 - 13 mg•cm-2 |

| Specific Area Resistance | 5.0 - 9.0 in Cl- form and 10 - 20 in SO42- form Ω•cm2 |

| Specific Conductivity | 1.0 - 2.5 in Cl- form and 10 - 20 in SO42- form mS•cm-1 |

| Selectivity | 93 - 98 % |

| Proton Transfer Rate | 60 - 400 µmol•min-1•cm-2 |

| Ion Exchange Capacity | 0.7 - 1.0 (in Cl- form) meq•g-1 |

| Dimensional Swelling in H2O at 25°C | 0 - 1 % |

| Uptake in H2O at 25°C | 5 - 15 wt % |

| Non-Std Modulus (MPa) | 1000 - 1800 MPa |

| Tensile Strength - max. (MPa) | 40 - 80 MPa |

| Yield Strength at 23°C / 50 % R.H. | 20 - 30 MPa |

| Elongation to Break (%) | 15 - 40 % |

| pH Stability Range at 25°C | 0 - 14 pH |

| Bubble Point Test in Water at 25°C | > 3 bar |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: