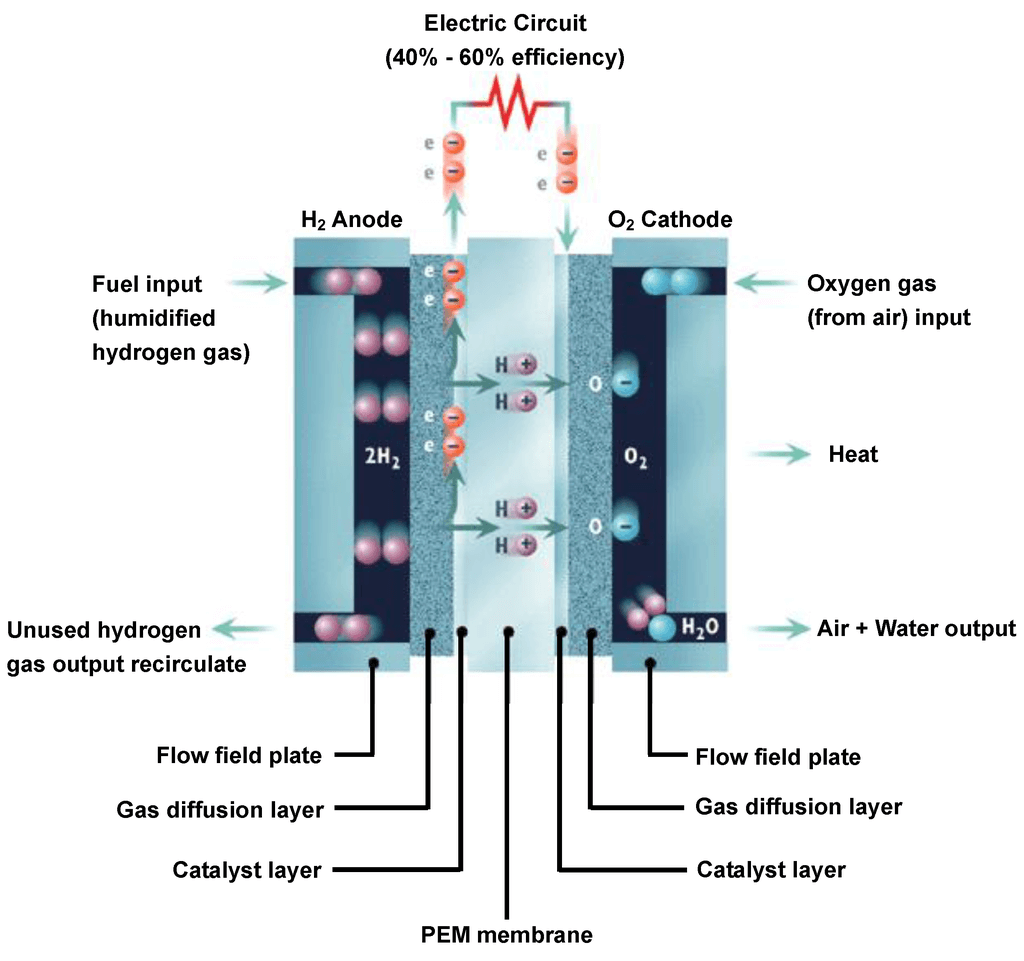

Different characterization techniques enable the quantitative comparison of every property and part of the fuel cell stack. By characterizing the fuel cell properly, you can understand why the fuel cell is performing well or poorly. These techniques help discriminate between activation, ohmic and concentration losses, fuel crossover, and defective materials. In-situ testing is important because the performance of the fuel cell cannot be determined simply by characterizing its parts. Not only can the actual parts cause performance losses -- but the contact between the parts can also cause decreased performance in fuel cells.

Different characterization techniques enable the quantitative comparison of every property and part of the fuel cell stack. By characterizing the fuel cell properly, you can understand why the fuel cell is performing well or poorly. These techniques help discriminate between activation, ohmic and concentration losses, fuel crossover, and defective materials. In-situ testing is important because the performance of the fuel cell cannot be determined simply by characterizing its parts. Not only can the actual parts cause performance losses -- but the contact between the parts can also cause decreased performance in fuel cells.

If you have limited access to test equipment, you can begin testing fuel cells with a multimeter, a temperature/humidity monitor for the room, and an oscilloscope. This only provides limited information about the fuel cell system -- but it will be enough to begin your initial examination. A good test setup with many methods of monitoring different fuel cell and fuel properties allows you to control and analyze how the fuel cell can be improved. Some of the parameters that can be monitored are the fuel temperatures, pressures, and flow rates.

Mass flow controllers, pressure gauges, and thermocouples help to monitor the fuel cell operating conditions. A potentiostat/galvanostat and impedance analyzer can help accurately track the electrical performance of the fuel cell. Some of the experiments that can be conducted include polarization testing, current interrupt tests, and cyclic voltammetry. An appropriate test setup can help accurately characterize most fuel cell parameters and operating conditions.

To test a fuel cell correctly, the test setup needs to be verified, the cell conditioned, and baseline testing conditions and operating parameters must be established. After the testing setup has been completed, accurate tracking of the temperature, pressure, flow rates, and other operating conditions need to be monitored throughout the testing process.

Verification of the Assembly

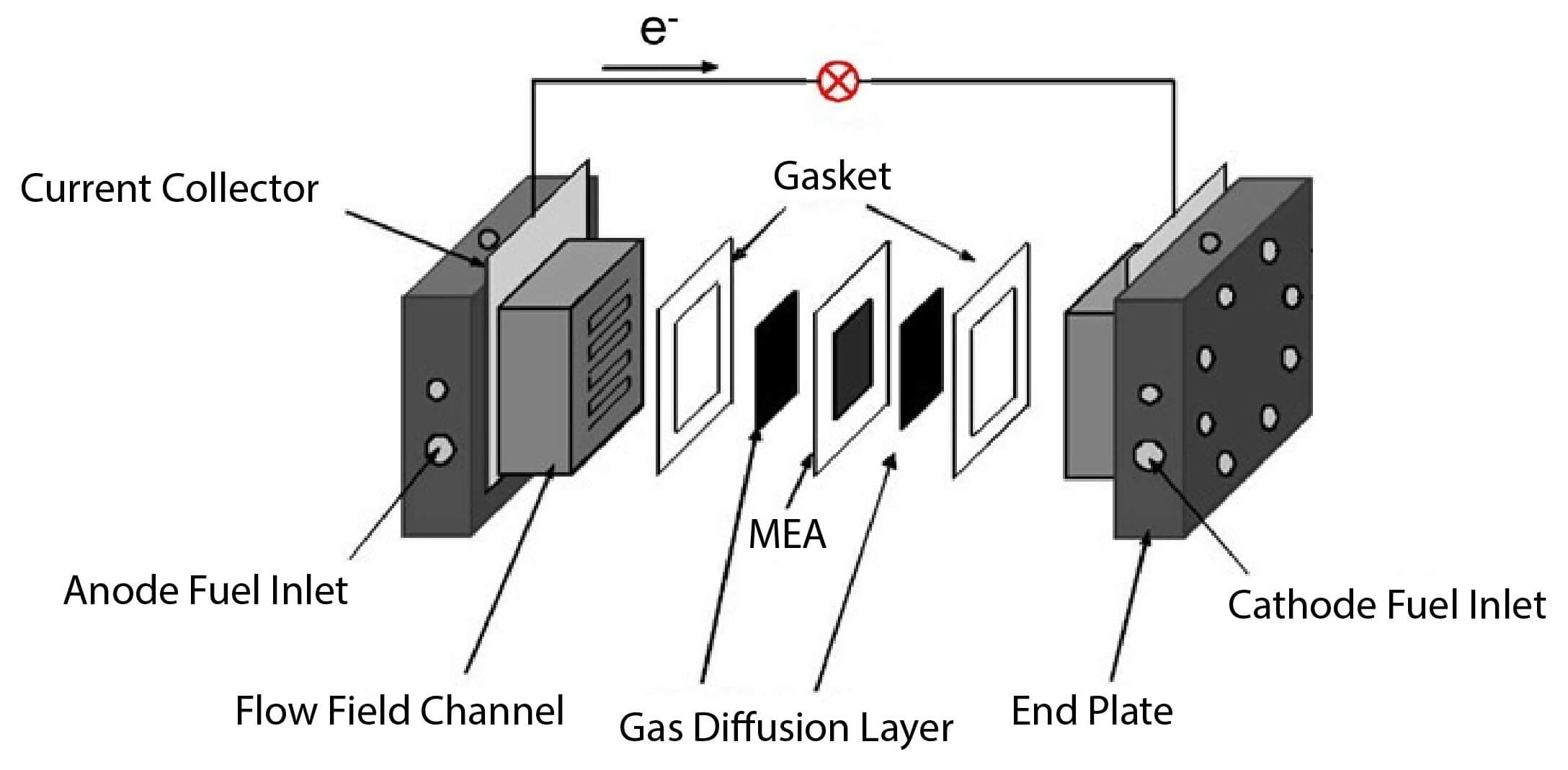

Verification of the AssemblyThe person performing the testing must verify that the fuel cell is seated correctly in the test apparatus. This should be done before any fuel cell is tested because it exposes the experimenter to voltage, current, hydrogen, and oxygen. Hazards are eliminated by checking the test apparatus through visual inspection and pressure and leakage tests for the hydrogen, oxygen, coolant, and other chemicals. To ensure a safe environment, it is usually a good idea to have a hydrogen and oxygen sensor in the lab environment. The instrumentation also needs to be adequately installed and correctly connected to the data acquisition system to generate the expected fuel cell test data.

Before fuel cell testing is performed, the cell must be adequately conditioned. Many fuel cells (depending upon the fuel cell type) begin providing power within seconds or minutes of supplying fuel. However, to test accurately and consistently, a procedure should be developed and used for the startup and conditioning of the cell before it is tested. Several methods exist for starting the fuel cell, and cell voltage, current, and other operating parameters should always be recorded during fuel cell testing.

• Cell Temperature

• Fuel and Oxidant Composition

• Fuel and Oxidant Inlet Temperatures

• Fuel and Oxidant Inlet Dew Point Temperatures (relative humidity)

• Fuel and Oxidant Exit Pressures

• Fuel and Oxidant Stoichiometries (flowrates)

• Current Density (mA/cm2) or Cell Voltage (mV/cell)

• Coolant Inlet and Exit Temperatures

• Coolant Inlet and Exit Pressures

These baseline conditions should be carefully studied and documented during the testing process, and are described briefly in the remainder of this post.

The fuel cell temperature must be documented and maintained throughout the fuel cell tests. At a minimum, the inlet and outlet temperatures should be monitored in addition to the fuel cell stack itself. To determine how the fuel cell could be improved, the temperatures across the fuel cell stack and in each cell should be monitored. Any inconsistencies in temperature can alter the fuel cell performance.

Gas pressures are typically monitored at the fuel inlets and outlets using pressure transducers to determine the amount of pressure drop that occurred within the fuel cell stack. Increasing the fuel cell pressure may improve cell performance, but the system should be studied to determine how this will affect the other fuel cell parameters and whether the system design is optimal for increased pressures.

Flow rates can be monitored using mass flow controllers. The fuel cell performance can be studied using by maintaining the same flow rate, and ramping the flow rates up or down and recording the resulting fuel cell parameters.

For most bipolar fuel cell stack configurations, there is an optimal compression force that helps the fuel cell achieve the best performance. Cells with low compression forces can suffer from increased ohmic loss, while cells that have high compression forces can suffer from pressure or concentration losses.

Fuel cell characterization techniques allow comparison of almost every characteristic of every part of the fuel cell stack. Selecting the best characterization technique, or using a combination of them, will provide you information about why the fuel cell is performing well or poorly. These techniques help discriminate between activation, ohmic and concentration losses, fuel crossover, defective materials as well as many other properties.

Posted by

Posted by

Enter the code in the box below: